Check the second part of Nasir’s tutorial on Control systems! Control systems are used to arrange and manage components in a way that the required condition or output is obtained. The word...

Residual Current Circuit Breaker (RCCB)

New article from Manish, one of the members of the EEC! In his last article he told you about Miniature Circuit Breakers (MCBs). Today he will take a look at another important type of circuit breaker...

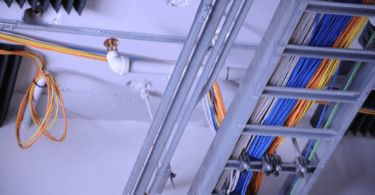

Types of electrical joints and terminations (back to basics)

Let’s go back to basics with this article by A.N, an experimented member of the community. He chose to focus on electrical cable joints and we’re glad he did! If you too want to publish...

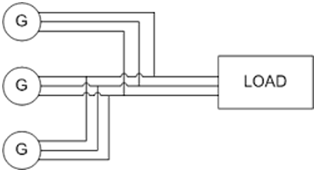

Paralleling of Generators and Synchronization

Hi everybody, our fellow electrical engineer A.N is one more time spoiling us with a nice article. Check his material below: Connecting generators in parallel increases the power capacity, control in...

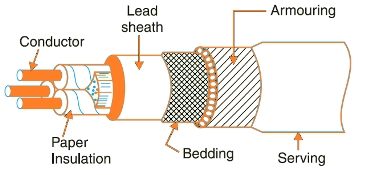

Electrical Cable jointing procedures

Hello everybody, enjoy this article from one of our fellow members of the community! And if you have remarks or questions to ask, do post them in the comment section. Joining electrical power cables...

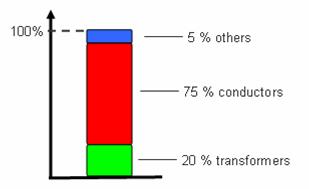

Underground cables: types, advantages & disadvantages

One of our fellow member of the EE Community is willing to do a several-parts series of articles about underground cables. Let’s begin with the basics: type, benefits and drawbacks…...

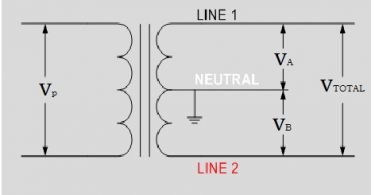

Centre Tapped Transformer

Here’s the 6th part Nasir’s tutorial on transformers. Enjoy and leave your impressions. Don’t forget you can send your own articles, works, reviews or tutorials; just send us a mail...

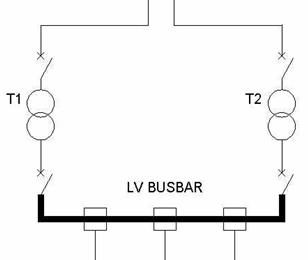

Switchboard and switchgear: functions & differences

Our community still can count on A.N for year 2017! Here’s an article this electrical installations expert sent us lately inwhich he will tell you what’s the function and differences of...

Introduction to Second Order Systems

Next article of Nasir from his tutorial on Control Systems. Introduction As we discussed earlier we have two methods of analyzing the working and functioning of a control system named as: Time domain...