Did you ever wonder about partitioning of low voltage switchboards? This important process is explained below by Eric S. who sent an article to the EEC team last week.

You too can be published in the blog, just send us a mail and we’ll discuss about it :)

Partitioning of low voltage switchboards is very important because of the following four important reasons:

- Partitioning protects the working staff and other personnel in the premises from getting into direct contact with various live dangerous parts of the equipment. IPXXB is the minimum protection degree standard set by the IEC, to protect humans from fatal electrical accidents.

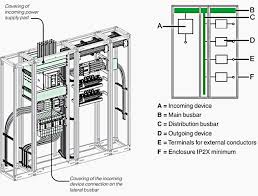

- Partitioning protects the low voltage switchboards form solid particles that often penetrate into the equipment. IP2X is the minimum protection degree standard set by the IEC, to protect solid alien bodies from entering into the switchboards.

- Partitioning protects electric arc propagation in the low voltage switchboards, as it separates various connections, busbars and equipment.

- Partitioning of low voltage switch boards helps maintenance staff to perform their regular maintenance and/or upgrades of the switchboards with minimal fuss.

Note: Electricity personnel, who want to know more about the standards that should be maintained while performing partitioning, can refer to section 61439-2 of IEC standards.

At this juncture, one should understand that the very term partitioning, depends on its usage conditions, switchboard maintenance and switchboard up-gradation. It often depends on the mutual agreement between the manufacturers and the end users and decides as to how the partitioning should be done, so that it meets both the IEC’s, as well as the manufacturer’s specifications.

While performing partitioning one should remember the following essentials:

- Products and components used during partitioning should comply with the set standards, and should have been tried and tested elsewhere before

- Partitioning should also comply with the standards and specifications set by the switchboard manufacturer, and should be done in accordance with the user manual supplied along with the equipment

- After the partitioning is complete, one has to conduct clearance test, as well as continuity bonding test. There has to be a final inspection scheduled, after which all results are recorded in the contractual document for future reference.

Note: Compliance certificate will only be issued after successful completion of above mentioned essentials.

Let us now have a look at the four types of partitioning that are set as a standard:

Type – 1 Partitioning

In this type of partitioning, internal components of the switchboard are not allowed to be separated. As mentioned earlier, this kind of partitioning primarily aims at saving people from electrical accidents.

- Front portion is covered with plates and can only be opened using certain tools

- The doors of the live parts are locked

- The terminals are covered systematically so that no one gets hurt on contact

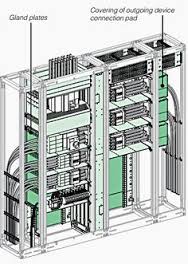

- Top and bottom pads of the incoming supply are totally covered to protect the personnel working on the switchboard, when it is open.

Type – 2 Partitioning

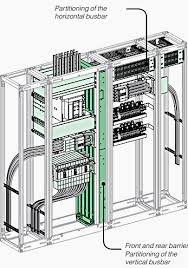

In this type of partitioning, it is allowed to separate the busbars and the functional components inside the switchboard.

- Partitioning aims at saving people from electrical accidents

- Blocks solid alien particles from entering into the switch board

Type – 3 Partitioning

In this type of partitioning, separation of all the internal functional components of the switchboard is allowed.

- Partitioning aims at saving people from electrical accidents

- Limitation of propagation of arcs

Type – 4 Partitioning

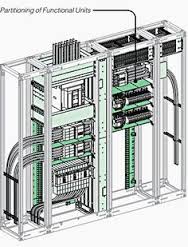

In this type of partitioning, in addition to 3 guidelines, separation of switchboard terminals to incorporate external conductors in a functional unit as integral parts is also allowed.

- Partitioning aims at saving people from electrical accidents

- Limitation of propagation of arcs

Conclusion

Finally, partitioning of low voltage switchboards not only helps in saving people from electrical hazards, but it also serves as an important tool of dissipating heat from the system.

However, while choosing the external metal covers for protection, one should take care that they are strong enough, because a single dent on the plate’s external surface, covering the live parts, can cost a life.

Did you learn something from this article? Feel free to add any other remarks!