Hi again, this is Jesús Pérez Díaz, as always it’s a pleasure to write in this blog. This article is about Lightning protection, enjoy and comment it.

image: cdc.gov

Introduction

Lightning Protection is one of the most controversial topics in electrical engineering since the lightning behavior is really complex and not easy to understand, so there are a lot of opinion and criteria to design a lightning protection system resulting in many ways to implement it.

NFPA 780 “Installation of Lightning Protection Systems” is a recognized standard guide used for designing lighting protection systems, it establishes practical criteria and describes the geometric method applied to define lightning rod locations.

What is a lightning?

Lightning is formed when clouds become charged by static electricity.

Positive and negative charges are located in the extreme sides of the cloud creating an Electric field, when a high value is achieved a spark takes place forming a pathway where charges move on, sorting out them and removing the potential differential, of course accompanied by a huge sound and flash.

Types of lightning

Lightning are classified according to the form of them:

- Intracloud: it’s when the lightning occurs internally within a cloud

- Intercloud: It happens when the lightning starts in a cloud and ends in another one.

- Cloud to Ground: this type of lightning involves cloud and the surface of planet earth. It can start in a cloud and finish at the earth, but it could also work all the way around. In order to keep the installation and building safe, a protection system against this kind of lightning is needed; imagine that a Cloud to Ground lightning impacts in an oil facility.

Take a look to this video which shows a slow motion of lightnings.

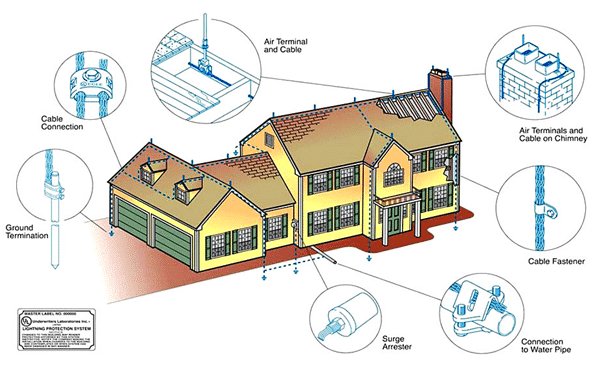

Lightning protection systems

In a general way, Lightning Protection Systems are basically composed by three items: Air terminals, wire conductors and grounding rods. Lightning Protection System is intended to attract and capture the lightning (by Air terminals) and carry all this current/energy (by wire conductors) to ground (Grounding system).

Air terminals are also known as lightning rod, strike termination, Franklin’s rod. They are made of conductive materials such as copper and alloys.

image: directindustry.es

There are a lot of manufactures and vendors that offer devices called Dissipation Array Systems (DAS) and Charge Transfer Systems (CTS) using the premise that these kind of systems are more effective than the conventional (Franklin Rod, above image) since can protect for larger radius from lightning. This statement is false and has not been approved and accepted by the regulatory institutes such as NFPA, CIGRE, IEC, ICLP, among others.

Next figure shows a typical arrangement of a Lightning Protection System.

image: westernreservelightningrod.com

Where air terminals should be placed?

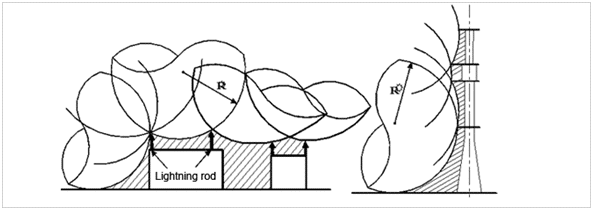

Air terminal location must be selected considering the dimension of the installation to be protected. The method mostly used to place air terminal is called “Rolling Sphere Method” and widely explained in NFPA 780. It is a geometric method and consists in taking a Sphere and roll it around the air terminal, the objects located inside the area formed by the sphere will be protected by the air terminal.

Sphere radius is selected considering the applied project standard; NFPA establishes a radius of 46 m for normal installation and 30 m for structures containing flammable liquid and vapors.

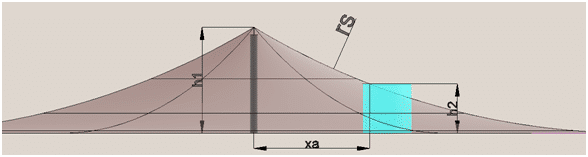

The horizontal protected distance is calculated applying the following equation:

Where:

xa: horizontal protected distance

rs: sphere radius (m)

H1: height of the air terminal installation

H2: height of the object to be protected

Also, when two or more lightning rods are located in the same installation, the sphere roll around all rods. See Next figure.

image: eng.i-sk.com

See an animation here:

Thanks for reading our dear memeber Jesús Pérez Díaz. Do you have any remarks or questions to ask him? If yes, post a comment in the section below.