My name is Günther Müller, I have 20 years of experience in electrical engineering, and I work for a Consultant in Germany. I currently work on the extension of the electrical installation of a site in Europe, owned by a large American industrial group.

First, we had to make the audit of the existing installation, and the dimensioning of the extension. Then, we had to make the estimation of the Arc Flash risk level for every electrical switchboard, in order then to choose the category of PPE (Personal Protection Equipment) which electrical maintenance people should wear when operating on or near these equipments.

But now I really wonder: will this really help to protect the maintenance operators against arc flash risks?

First, I doubt it is realistic in practice to ask maintenance teams to wear different types of protections depending on the switchboard they work on. And I doubt they will even wear these protections, considering they seem to make it really hard to work with (impossible to do precise work with your fingers, lack of visibility, heat, etc …)

Second, I wonder why the standard calculates the Arc Flash energy at a distance of 18 inches (~50 cm): what about the possible damages to the hands and arms of a worker who is at the origin of the short-circuit, for example due to a mistake when checking that the power is down?

Third, as the results give a PPE category = 0 for 400V switchboards with a short-circuit level of 20kA, isn’t there a risk that some maintenance people will consider that there is no risk, when in reality if they are at the origin of a short-circuit with their tool they will be at minimum seriously burnt?

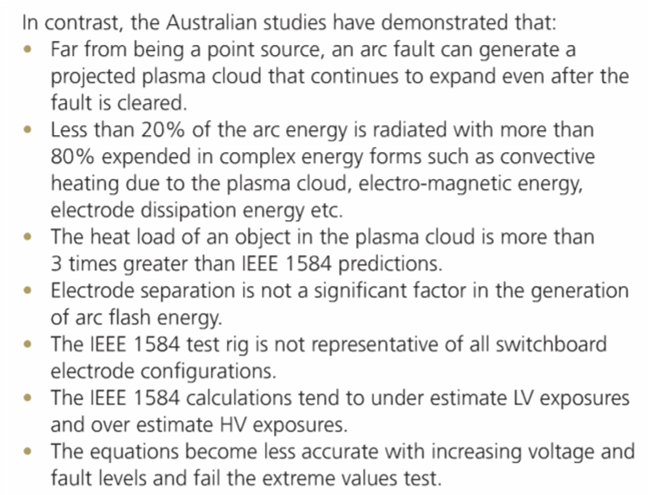

Also, as I found this standard somewhat questionable, I searched for more information about it on the web, and found this article and survey done in Australia and published in Industrial Electrix issue of April/June 2011, which I found on this website:

http://www.flipemag.com.au/APT/emagIE_secondquarter_2011/)

(click the link and go to page 44)

This is an abstract from the article:

So I even wonder if the calculations and estimations of this IEEE 1584 are realistic, or if the real risk is in some cases underestimated, which makes the standard almost worse than no standard at all, as people following the rules will feel safe with their PPE when they may risk more than 2nd degree burns.

Finally, even though my first thought was that it was a good thing there was an existing standard in the US, I feel that the current situation worldwide is:

* in the US, there is an existing standard but it is potentially dangerous

==> Contradict me if you disagree

* outside US, there is no Arc Flash risk specific analysis or recommendations

==> Tell me if you know about existing surveys or standards in your countries

Hi Günther,

Your comments and shared experience with arc-flash hazard analysis is very interesting for me. I have no experience with the NFPA 70E standard but I work for electrical engineering company, manufacturer of LV and MV switchboards.

What I can comment is that testing of LV switchboards under arcing conditions is considered as special test in accordance with IEC 61641. Unfortunately this is destruction test and tested switchboards can not be used any more. So in Bulgaria we try to implement type tested switchboards and rely on real test to prove the personnel protection under arc conditions.

Hi Krum

Thanks for your comment.

Which real test do you pass to prove personnel protection under arc condition ?

Does it help to define Personal Protection Equipment (PPE) to be used ?

“I doubt it is realistic in practice to ask maintenance teams to wear different types of protections depending on the switchboard they work on”

You make a very good point. Most teams don’t want to lug around extra gear or stop to change between projects. They will make do with whatever PPE they have. Unfortunately it may not always be the most appropriate gear and then safety becomes an issue.

Whilst inaccuracies may lead to workers underestimating the risks involved, a standard like the NFPA 70E is, as Roger mentioned, as much about improving awareness, training, knowledge and understanding of the potential risks and industry best practice on minimising the dangers.

For crews to completely disregard the safety standards, carry around inadequate PPE, refuse to change it accordingly or work on systems without the correct hazard analysis, they’re risking their own lives and others.

The UK has an equivalent but also uses the IEEE1584 to calculate the degree or arc flash hazard.

IEEE 1584 is like every other standard, a recommended minimum requirement to limit the severity of injuries due to an arc flash should one occur.

There has been much research on the subject of arc flash and the standards like IEEE 1584 and NFPA 70e give guidance to the designer, engineer and others to help limit the dangers to maintenance personnel.

There are no absolutes when dealing with arc flash hazards.

The hazards are very real and staff need to be aware of the dangers of arc flash and the possible injuries when working on electrical supplies.

PPE can and does limit injuries in the event of an arc flash but staff must be made aware of the limitations of the various PPE categories, hence the requirements of signs of Arc Flash Hazards and PPE categories.

Commonsense and mental alertness by trained maintenance staff will go a long way in preventing arc flashes.

In Australia live electrical testing is not classed as work from a safety point of view, so skirts around some of main safety requirements normally placed on “live work” so live testing can be performed.

I’ve come to the conclusion that the cost for some companies to upgrade to state of the art test equipment, which could reduce test time or eliminate some procedures, could be prohibitive possibly until an incident occurs or full tests as specified are not performed reducing risk.

Its all well and good for management to inform technicians to wear restrictive ppe,to monitor much harder,if this is the case, common sense does not dictate.

What is needed is more engineered solutions, not letting technicians be test dummies.

What i’ve picked up regarding incidents, natural reactions is for your hands to save your face, then you can be unlucky enough to suck in the ionised air from a gasp in sudden shock.

I apeprcaite you taking to time to contribute That’s very helpful.

we know arc is affected from what but how to protect from it If the way of protection as eng and the experience man says in the first page that is first step of idea but the second step must have aprotection things like element or subject which help the person or isolation .

we know it connected through the air so . how we solve this problem?

Brilliant article, Where has this website been all of my life

Many years ago we developed a Computer-Based Training course entitled Earthing for Electricians in which we explain Arcing Faults in very graphical terms using animations with audio narration. Should there sufficient interest from engineers & trainers, we would be happy to extract the relevant micro-lessons and make them available free-of-charge. Please visit http://www.matra.co.za and mail me at dave@matra.co.za for further information etc.

Hi Gunther

I’d have to agree with rford.

Until future engineered solutions are available to remove or majorly decrease risk, technician specific training in arc risk is needed and appropriate standard cal available to be worn with the restrictive higher cal available for the higher risk kA jobs and management needs to constantly monitor the the work systems and procedures.

Additionally, i think all electrical equipment worked on, where arc risk is associated, should be assessed as to maximum fault kA condition and stated on that equipment and the category of protection required.

There also needs to be an associated register to be updated as to changes in kA ratings due to installation upgrades.

From a technician’s point of view I am generally interested, these days, primarily in risk analysis and then getting the job done. If an incident occurs it will be extremely costly and embarrassing.

1. If i get injured or killed many people and procedures will be affected.

2. Equipment damage and down time will also cause the above.

From an engineering view, over engineering the safety requirements would be adviseable because measurement of such fault conditions contain too many variables.

Regards

Speaking with electrical technicians in the past, they were often pressured to work on live equipment. The Arc Flash standards helps establish in the minds of management the substantial risks for electrical technicians. The technicians understood the KA ratings of fault currents, but management often times had no concept. Now that a standard is established and labels are placed, even those with little or no electrical training can understand that the risks vary with the location and equipment. In areas where the hazard is category 4 or greater, technicians can now back up their objections with documentation.