The transformer is the most vital component of a grid-station. Poor evaluation and improper choice of power transformers can wreak havoc on the operational parameters and eventually result in catastrophic events.

power transformer substation installation

The selection of suitable transformer is always an integral part of substation design and separate consultants are often hired for the purpose.

This is the topic that K. sent our team several days ago. He chose to tell you in detail the operational requirements and parameters followed for sanctioning a suitable transformer for a substation.

Power transformer for a substation: subtypes and main characteristics

Primary factors for the choice of power transformer for a substation are:

- a. User installation capabilities and preferences.

- b. Operational continuity expected.

- c. Location and environment of a particular substation.

Transformers are different and every type is tailored for a specific purpose and operational expectations of the user. Generally transformer’s types vary as:

- a. Separate winding or auto power transformers.

- b. Single phase or multiphase. Three phase power transformers are widely used for the substations.

- c. Frequency requirements. Generally, frequency is 50-60 hertz for generation, transmission and distribution of electrical power.

- d. Dry or liquid based insulation. In almost all power transformers used for grid operations, synthetic-oil insulation is used.

- e. Rated power for primary and secondary windings.

- f. Cooling capabilities.

- g. Tap changing options. Tap changer is almost a necessary requirement for power transformers connected to a transmission line.

- h. Short circuit voltage percentage and no load current percentage.

- i. Efficiency standards.

- j. Level of noise and current leakages.

- k. Indoor/outdoor installation. Outdoor installation is more favorable and all power transformers are expected to be rigid and degradation resistant.

Types based on internal cooling

Power transformers process all the power entering and exiting a substation and consistent operation requires an adequate cooling mechanism. Heating creates problems with efficiency and load limits of a transformer and controlling the core temperature is a mandatory requirement. Power transformers employ different cooling techniques and are classified as:

a. AN: Cooling is achieved by circulating outside air and these transformers are also known as air cooled transformers.

b. AF: Cooling is achieved by forced (with the help of industrial fans) air circulation.

c. ONAN: Cooling is achieved by the circulation of oil and outside air. Air acts as a heat dissipation medium.

d. OFAF: Cooling is acquired by forced (or helped) circulation of synthetic oil and air.

It is important to note that oil takes the heat from transformer core and then dissipates it in the circulating air with the help of radiators installed. Mostly, substations require the installation of AN/ONAN type transformers for their simpler and maintenance free cooling mechanisms.

Choice based on operational requirements

Electrical load and power flow requirements are always decisive factors for the proper choice of power transformers to be installed. Transformer(s) should be able to bear the rated and short circuit current of the bus bar being fed.

Following requirements are to be considered for the choice and proper configuration of power transformers serving in a substation.

Winding connection schemes

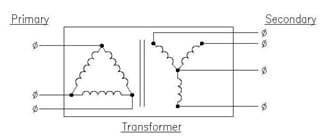

Delta-Wye connections

Normally substations use two types of winding connection schemes to prevent accidents and loss of equipment in an event of short circuit (both internal and external):

a. Delta-primary scheme.

b. Grounded-star secondary scheme.

It is important to consider the rated and short circuit currents for the primary and secondary coils separately.

Losses and efficiency

Different countries have their own power efficiency standards and power transformer(s) chosen should be compliant with the respective energy conservation regulations. Inefficient products are also liable to more faults and are more costly over the operational lifespan.

Different analysis show that energy efficient power transformers are more economical even if their prices are considerably higher at the time of installation.

Noise

Transformer are always the noisiest components in a grid station. Level of noise (measured in decibels) should always be under the limits set by the regulatory authorities and this factor should be given its due attention during the planning phase.

Protection and compatibility

Power transformers are the most important but hazardous component of a power grid station and should be able to protect themselves in the event of a fault.

A power transformer on fire

Different case studies and substation experiences suggest that non-protected or non-compatible power transformers may cause uncontrollable fires resulting in partial or total loss of the equipment.

Conclusion

Choice of a power transformer is a core phase of a substation design and should not be taken lightly. A proper evaluation and selection according to all the factors involved guarantees smooth and reliable operations of a grid station. Poor choice may result in accidents and loss of personnel and property becomes inevitable.

K.

Your thoughts on K’s article?