Home › Electrical Engineering Forum › General Discussion › The Importance of Equipment Specifications for an Engineer

- This topic has 1 reply, 2 voices, and was last updated 9 years, 3 months ago by

Anonymous.

-

AuthorPosts

-

2015/08/12 at 3:25 pm #11272

admin

KeymasterAs with any other business or profession, a clear write-up of requirements is important for purchase and procurement. This is especially important for electrical equipment due to the high significance of tolerances, ratings and size.

Whether for new projects or replacements, a specification document is crucial. The following article sent by Marvin M. highlights the purpose, features and format of an electrical equipment specification document.

Purpose

The chief purpose of equipment specifications is to ensure the purchaser acquires the required equipment, rather than what the supplier thinks is right. You might think that the difference in interpretation is a minor detail. However, considering the detriments associated with wrongly rated electrical equipment, it is vital you get the right specifications.

Do note that suppliers of electrical equipment often serve a wide market and industries, from residential installations, commercial projects to large plants. For this reason, narrow down to your exact niche and area of use. A variable drive for underwater installations may require different requirements from similar equipment for land use due to the prevailing environmental and operating conditions. For example, a simple LV motor operating in desert conditions may require a longer frame size than for cold and windy locations due to extra cooling requirements.

Features

A typical equipment specification consists of the standard equipment rating, and more details based on the options available. Over specifications over the available options is considered impractical and unnecessarily expensive, unless the project is highly sensitive and dependent on the extras. In such cases, the manufacturer may assemble customized equipment, often at a very high cost. The feasible option is to purchase the most suitable options, and then design the power system around the equipment to suit the requirements.

The following are the primary features of equipment specification :

- Crucial requirements based on the market standards

- Desirable requirements based on the available options

- Incidental features based on ‘nice to have’ feature such as equipment color. These features are usually not crucial to performance.

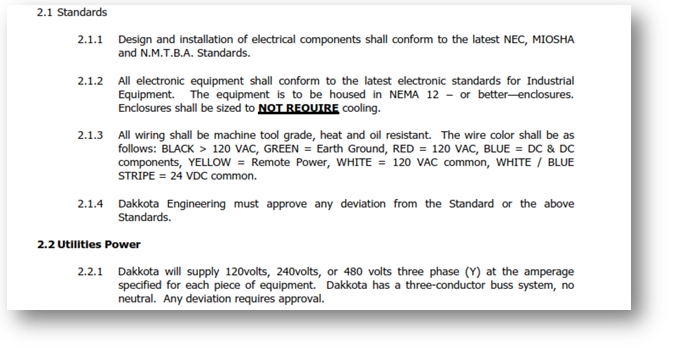

(Section of an electrical specification document)

Format

Introduction: a brief description of equipment installation location, installation type, and nature of the installation environment

Scope Of Supply: a summarized list of the primary equipment constituents, as well as the components to leave out. This reduces chances of misunderstandings during the quotation and delivery

Service Conditions: an in-depth description of the installation conditions including humidity, temperatures, winds, moisture levels and chemical contamination. It can also include a brief description of the indoor or outdoor conditions depending on usage.

Standards: highlights the most appropriate and relevant international norms desired. Ensure that the standards are updated and clearly listed to minimize chances of confusion during quality assurance tests. To be on the safe side, specify the standards to avoid uncertainty due to similar standards depending on region and metric units.

Definitions: misinterpretation is rife when sourcing electrical equipment. It is risky to assume that the manufacturer or supplier is well versed in the industry-specific jargon. Clearly define such terms and phrases in the specification, especially when it has different meanings in different standardizations.

Performance Requirements: clearly state the expected service life of the equipment, both lifetime, and in-between maintenance schedules. Though this depends on the equipment type, it is easy for an engineer to look up and specify the expectations of large electrical equipment such as generators, motors and such. Do note that the mode of operation, as well as the rated duty for LV and MV equipment, usually has a significant impact on the performance requirements; therefore ensure you highlight this factor.

Design Requirements: clearly define the degree of protection required based on the area of usage. Outdoor, indoor and levels of hazards require different design and construction requirements, therefore, highlight this factor. In the same vein, underline crucial fittings such as protective devices, circuit segregation, lifting points, and such. However, ensure that you check out the data sheet first as most of these will already be included.

Inspection and Testing: the purchaser should pay particular attention to this factor, as mistakes are costly. The first test is a physical inspection before purchase. Ensure that you clearly state the required inspections and test before purchase and delivery. To be on the safe side, use international standards as references and acceptable limits for the best results and to save time.

Appendices: contains definitions, and extra information not highlighted in the other components such as noise information, interlocking data and such

Any functioning electrical system, whether SCADA or variable speed drive system is an amalgam of compatible individual elements. With this in mind, approach the procurement with a combination of compatibility and eventual functionality.

Thanks for reading my article,

Marvin M.Thank you Marvin, very interesting. Can you all relate?

2015/11/13 at 8:15 pm #13743Anonymous

GuestNice Article. I am very impress. Thanks for providing this useful information.

-

AuthorPosts

- You must be logged in to reply to this topic.

As with any other business or profession, a clear write-up of requirements is important for purchase and procurement. This is especially important for electrical equipment due to the high significance of tolerances, ratings and size.

As with any other business or profession, a clear write-up of requirements is important for purchase and procurement. This is especially important for electrical equipment due to the high significance of tolerances, ratings and size.