Home › Electrical Engineering Forum › General Discussion › Panel builders are all cheaters?

- This topic has 26 replies, 10 voices, and was last updated 10 years, 8 months ago by

Anonymous.

-

AuthorPosts

-

2011/04/13 at 12:54 pm #10451

Laurent

ParticipantI am a young professional in charge of electrical maintenance and new works of a Lime production site in Belgium.

From time to time I subcontract the renovation of electrical control panels to panel builders. Frankly speaking, I find the bill amount is going up and up! When asked why, my panel builder gives straightforward answer like “Sir, have you seen the price increase of copper these days? The price of the cables has doubled in recent months, moreover, all materials costs have increased!”

Similarly, I often hear that his workers are not happy with peanuts, and that social charges and taxes are also increasing, blah, blah, blah…

But I discovered recently that there are solutions on the market to make panels quicker to assemble, and thus cheaper than the ones I pay for, I’m pretty sure.

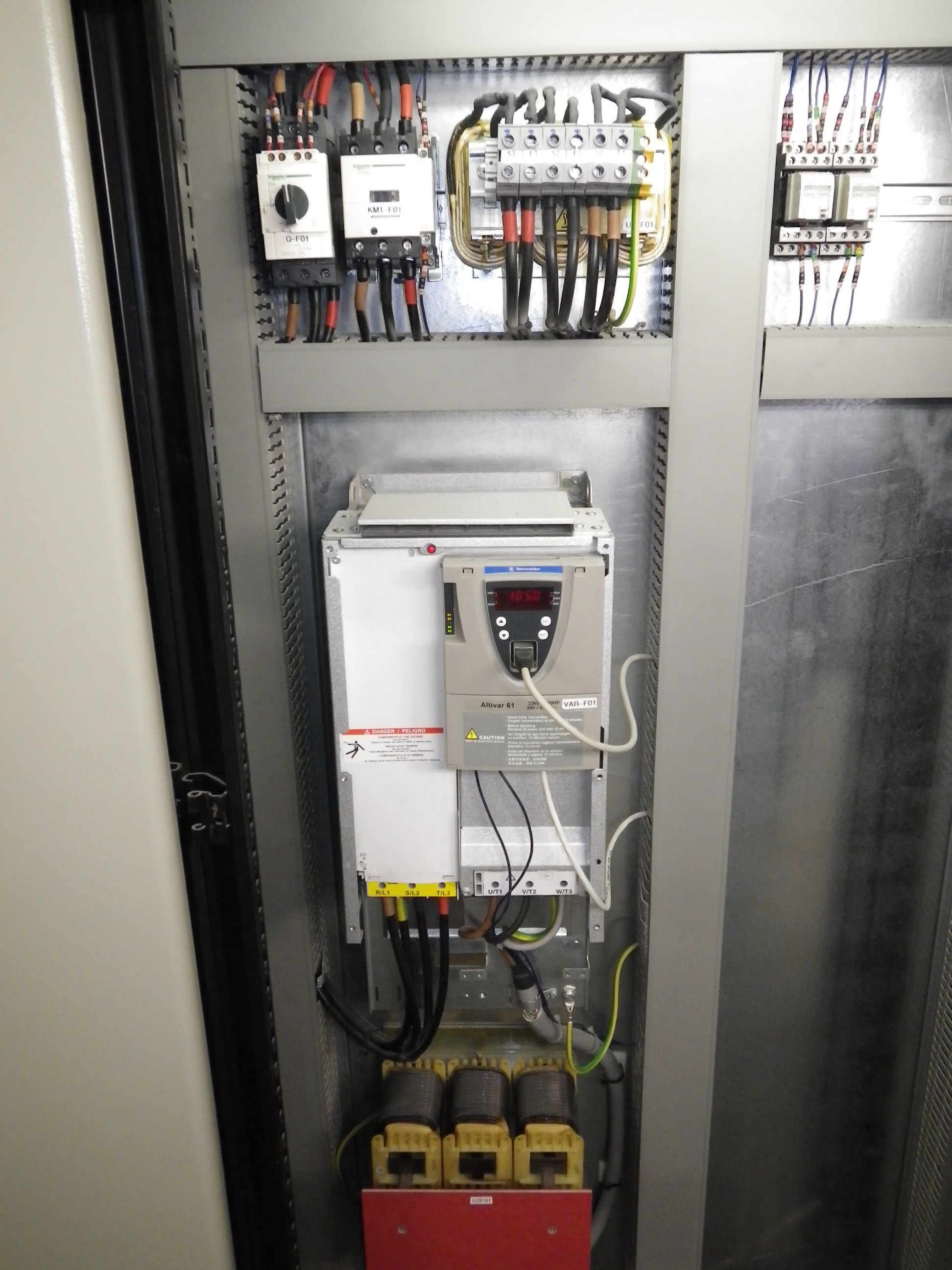

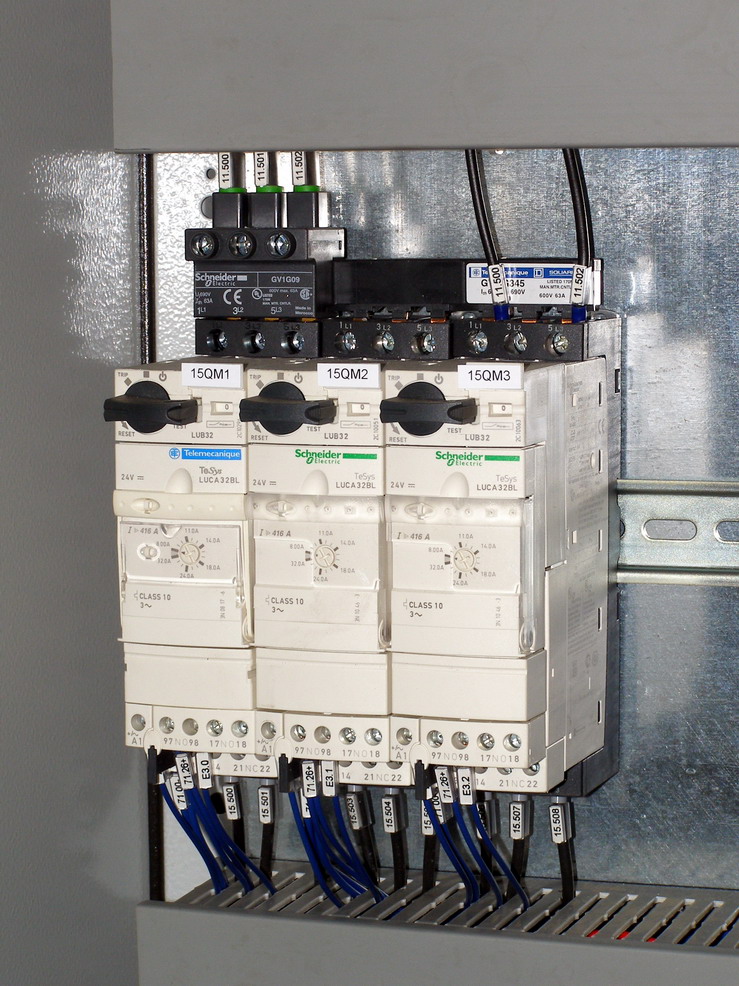

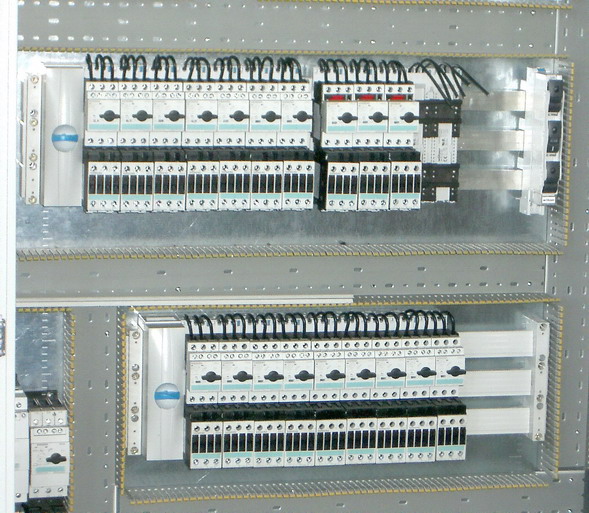

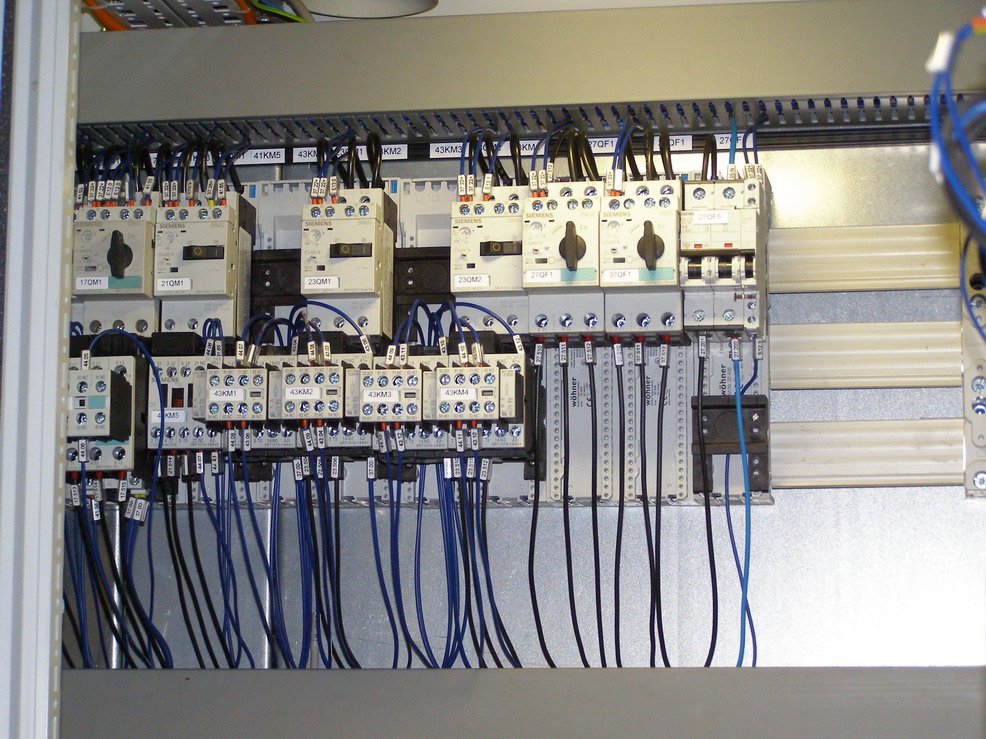

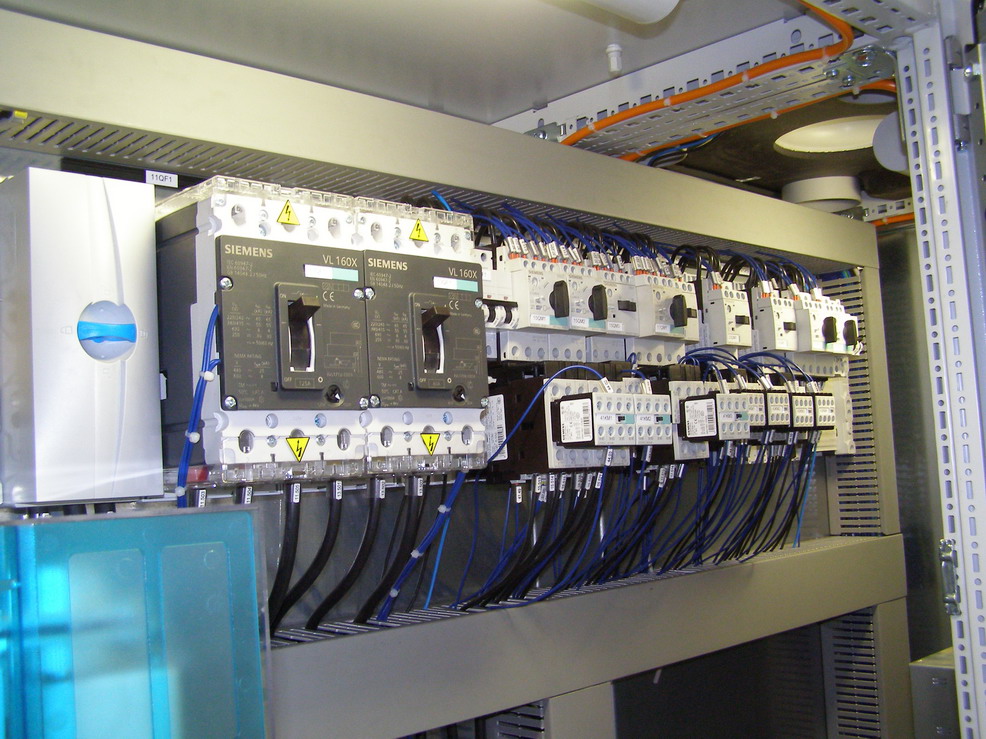

For example, the 2 photos I included here (above and below) show some recent installations that my panel builder delivered:

I really feel it would be easy to optimize the wiring, and probably to reduce the size of the panels. After a few clicks on the net, I saw that several manufacturers of motor starters (Siemens, Schneider, Moeller …) offer a whole list of solutions to reduce the wiring time and avoid this complex number of wires!

On the contrary, I admit it is not easy to find your way among all these products: there are so many of them! From simple connection accessory between a circuit breaker and contactor to more comprehensive solutions using spring terminals, mounting plates, etc.

When I went last time to see my favourite distributor, I asked him if he knew all these accessories. The answer: “What is that? I have no idea, I’ll find out! “… and I understood during coffee discussion that there are very few chances he will have them in stock in the future …

The advertisements of manufacturers say it’s easy, quick, cheap …

So, why panel builders do not use these solutions?

Have a good day!

Adrien

2011/04/14 at 1:20 pm #11959admin

KeymasterI am not the specialist, but as I know well electrical material sales side – there is always the effect : – does the people in jungle not wear shoes because there are not shoes for sale or does nobody sell shoes because nobody buys them ?

Producer of such components should push his innovative product and the price of that product should be in last end still competitive.

For panel builder means the addittional product range higher stock cost and still supply uncertainty, at the same time the supplier has not the lovest price level to offer as the volume is low.

But always where is the problem there is an opportunity.

Be the first who will use such system!

2011/04/18 at 12:16 pm #11967NV Mani

ParticipantPanel builders basically assemble components.

If the components are tailor-made it will take more time to assemble.

But if components are standardised,to suit commonly for a bigger range of end users,in modular design,

in cost effective way,time and thus cost can be minimized.2011/04/19 at 2:19 pm #11975Anonymous

GuestProbably the solutions offered by the suppliers in term of accessories cost more to the panelbuilder rather than just bending some wires. On the other hand using ready factory made accessories will result to a type tested assembly, which is usually more expensive.

2011/04/19 at 5:13 pm #11977Anonymous

GuestI am a planner of electric schemes. I am using for some time the system with the compact motor starters and everything it’s ok. I use Schneider. I was trying to use the series 3RA6 of the Siemens but the delivery time were too long so I have to changed mind.

For a great number of motor starters I’m using the Bus Bar Systems from Siemens or Wohner and that it increases the speed of wiring. For the connection between the magnetic protection and the contactor the builders make an accessory always available.

I apologize for my english.2011/04/19 at 6:23 pm #11978Anonymous

GuestThe sample shown is a nice view of Schneider components

The Altivar VFD would have benefited from Ethernet card which reduces wiring and increases programming time on the first Vfd only as you then know how to connect to the PLC

The contactors would benefit by using a Tesys U contactor up to 32A or Tesys T for above 32A add a Modbus com module daisy chain the communication module’s together and back to the Plc Modbus card or also Ethernet on the T is possible.

Very little programing on the Tesys U or T program Power suite is free or use the new So Machine as low cost compared to Siemens or AB. Therefore the panel cost is reduced if you the end user does the hook up and programming of the PLC which should take far less time but may cost more due to the higher intelligence needed to program.

The other part is that you need to be open to change and jumping a level in ease of use. ( Hard concept to grasp for old dogs :) )

Good luck contact the local Schneider Rep and I am sure you will be very happy!!!2011/04/19 at 6:40 pm #11979Anonymous

GuestIf you think to do the job is so easy than you do it, but the panel builder know for sure wat to do, has in stock materials to do it right, he know the law and regulation.

If you still think you can just order some components and asamble is a panel builder than do it by yourself, when it will burn the first one you will think more.

What I saw in the picture is verry busy place with components, from one of the top supplier of components.

By the way do you know the request of China for copper is so big – and the offer is not equal so the price is going up – true.

Wire now is 35% bigger than 75 days ago.

For components try another good example Eaton Moeller, with Darwin technology.2011/04/19 at 11:48 pm #11985Col

ParticipantHi Adrien,

Just read this post with interest and can make a couple of observations from both an engineering point of view and also a sales point of view. I currently work as an Electrical Engineer for a large water authority in Australia but in a previous life was in a senior sales role with Schneider.

Generally speaking, at least in Australia, panelbuilders can be divided into two types; those that are more interested in selling “labour” and those that are more interested in “jobs out the door” or volume. Those selling their labour (or perhaps technical expertise) are usually involved in more complex and custom deisigns and therefore are not usually comfortable with new concepts that may save labour time. On the other hand, those that are more interested in volume (more repetitive or modular designs) are always keen to embrace new technologies that can save them time or space etc.

As mentioned previously in the blog, it looks like the TesysU from Schneider would be a very nice fit for you. I have done many of these types of jobs previously (in the food industry) with sometimes up to 200 starters in the panel using TesysU starters in conjunction with the parallel wiring option rather than comms. This is a cost effective and robust wiring solution when all you need is a few I/O per starter which appears to be your application from your photo. My jobs also used Schneider's Advantys STB remote I/O solution which makes it a very nice job that can be connected to any automation platform saving lots of space and cost in terms of rack based PLC I/O.

I also recommend the type of busbar systems already mentiioned. Schneider also sell this system and they have a specific plate available for the TesysU.

I can try and find some photos if your interested but I suggest you talk to your local Schneider rep.

I hope I don't sound like I still work for Schneider !!

Regards

Col

2011/04/20 at 8:51 am #11988D_Czy

ParticipantHi Adrien,

In some cases pre-fab panel boards are suitable for the proposed installation, but in some instances a bespoke panel is required and a panel builder will be more adaptable with obtaining componements for the panel. For example if you go to your local bank and ask for a competative mortgage they will try and sell you one of their own “competative” products, but if you go to an independent broker they will find a suitable product after searching the whole market.

Regards

David

2011/04/20 at 9:38 am #11984Anonymous

GuestCombine the components and put the labels on the components, not on the cable ducts!

It’s hard to work on this panel, when you have opended the ducts!2011/04/20 at 10:49 am #11983Anonymous

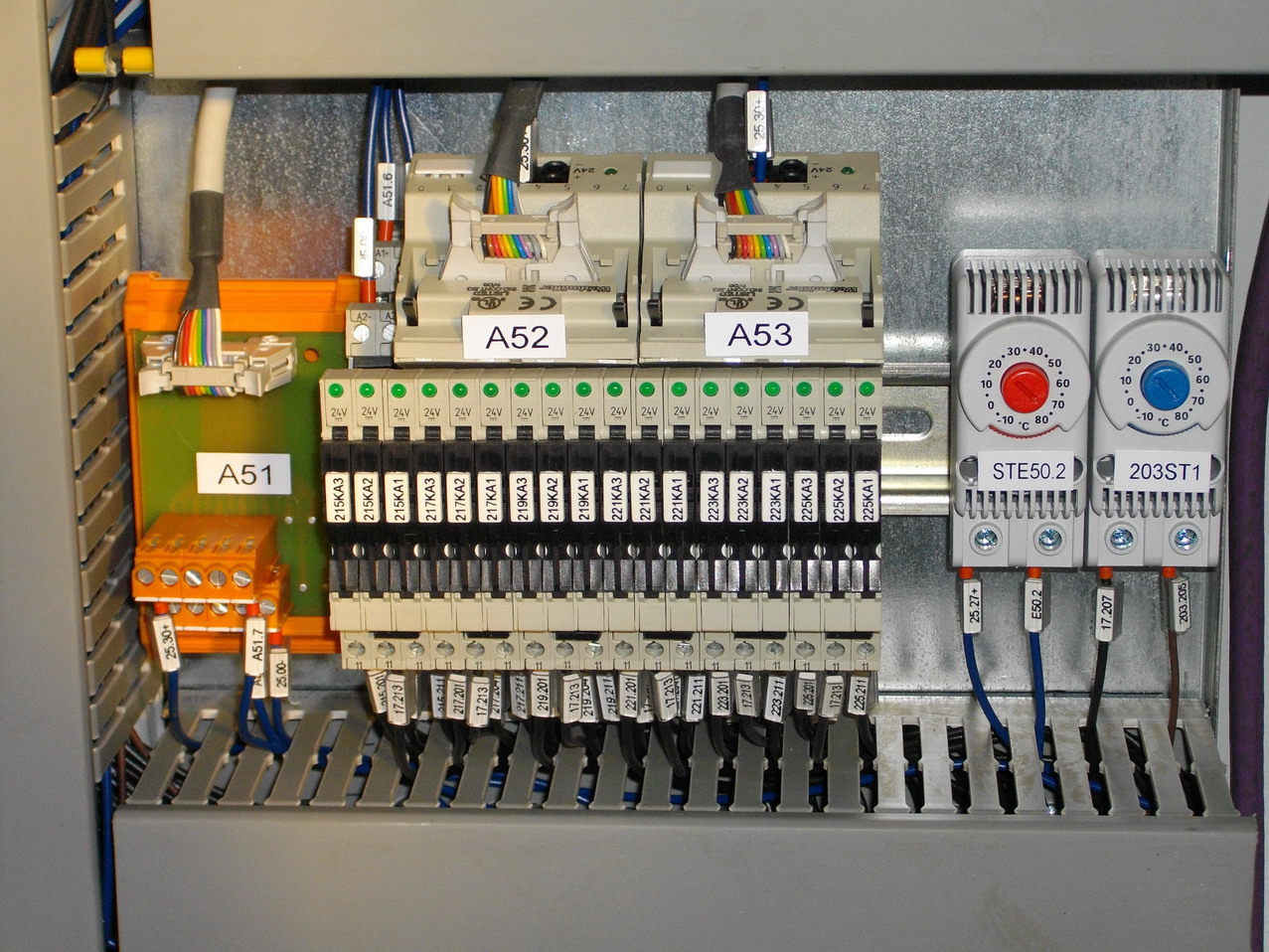

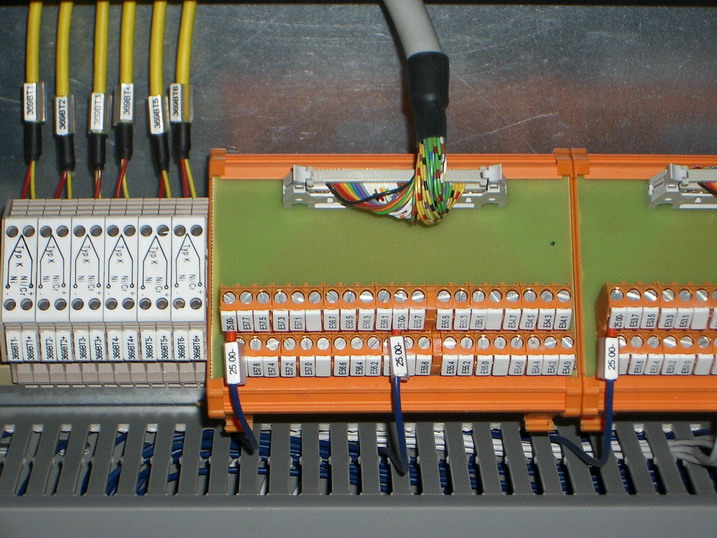

GuestPLC interface Weidmuller, Phoenix, Eurogi or other with terminal block or relay (classic or solid state). Like I just said I’m using Bus Bar System and compact motor starters Tesys U, 3RA6. Sometimes is enough to take a look on the constructors sites to find new solutions. The panel builders have to know all this new articles/components.

Photo 1: Schneider/Telemecanique compact motor starters (take a look at the supply system GV1G09)

Photo 2: Schneider/Telemecanique compact motor starters (you can see: 6 wire for motor power, 2 wire for start, 2 wire for motor protection tripping)

Photo 3: Weidmuller PLC interfacing (A51 – 10 pin terminal block, A52-A53 – 2×8 interface relay with adapter)

Photo 4: Weidmuller PLC interfacing (40 pin terminal block)

Photo 5: Siemens/Wöhner Bus Bar System with mounted combinations of motor starters + contactors

Photo 6: Siemens/Wöhner Bus Bar System with mounted combinations of motor starters + contactors

Photo 7: Siemens/Wöhner Bus Bar System with mounted power supply switch (3VL1 series circuit breaker)

2011/04/20 at 3:56 pm #11990Anonymous

GuestAs a former machine builder, I was responsible for doing the panels. My experience has shown me that there is always a tradeoff. The material costs of newer technology can sometimes but not always exceed the cost of labor, and older technology. I think the quality of the panels look very good.

2011/04/21 at 1:04 pm #11999Anonymous

Guest@ Ciprian,

You can send the photos to engineering@electrical-equipment.org. I will attach them to your post.

Thank You!

Regards,

Moderator

2011/04/23 at 1:31 pm #12006admin

Keymaster@Ciprian : you said that you use bus bar system & mounting accessories…and also TeSys U, how do you choose between all these solutions ?

@Paulo, Ciprina, Colin, Sch1 : you talk about TeSys U, in which case is it competetive ?

@all : thank you for your comments !…if you have some pictures to explain more, it should be good ! thanks

2011/04/28 at 8:59 am #12026Anonymous

GuestFor a large number of motors to be controlled I’m using the Bus Bar System.

As for TeSys U must know that they are in two sizes: one that goes up to 12A and the second goes up to 32A.

I do not know if it is permissible to post links of the various manufacturers to provide complete information, however, I also put these details.

I chose “TeSys U” because the series of Schneider 3RA6 compact starter

(Click here for more information)

had very long delivery times.

For more information about Tesys U : Click hereBus Bar for the system take a look at:

Click here ,

Click here and

Click hereBest regards.

-

AuthorPosts

- You must be logged in to reply to this topic.