Home › Electrical Engineering Forum › General Discussion › Ground Electrode

- This topic has 0 replies, 1 voice, and was last updated 11 years, 7 months ago by

Steven Mill.

-

AuthorPosts

-

2013/07/02 at 3:47 pm #11035

Steven Mill

ParticipantIntroduction

A good ground connection is vital to protection of any electrical installation against fault currents, lightening surges. The connection to groundmass is done by use of “Ground Electrode”. Let us study this in more detail.

Ground Electrode

There are several different types of ground electrodes that are available in the market. They vary based on type of electrode material used, configuration and design. Choice of a particular type of electrode is governed by local country specific standard in use. In the U.S. National Electrical Code (NEC) is the referred standard.

Generally speaking, almost all the standards refer to a basic form of grounding based on ground electrode. A ground electrode comprises of a metallic rod that is buried in to the ground at a certain depth and connected externally to the grounding system by ground wire (usually copper wire). The purpose of this rod is to connect the grounding system with the groundmass at a point where the soil offers very low resistivity, thus allowing safe passage of fault current.

Factors influencing Performance of Ground Electrode

A ground electrode essentially serves as a good conducting medium that is in contact with groundmass. A good ground electrode connection ensures safe and smooth evacuation of current from ground connections in to the ground.

Following are the factors that impact the performance of any ground electrode:

- Material used in Grounding system

- Soil Resistivity

- Depth of Ground Electrode

- Moisture content

- Soil Temperature

Material used in Grounding System

Material used in grounding system includes the ground electrode itself and its connecting wires. There are various types of electrodes available like:

Copper Rod or Galvanized Iron (GI) pipe rod or Copper Plate.The choice of electrode depends on the type of application, location. Local standards and rules that govern the choice of electrodes.

Soil Resistivity

It is one of the most important factors that influence the performance of grounding system.

There are country specific standards on maximum value of soil resistivity to be considered while doing grounding. National Electric Code (NEC) recommends the maximum value of Soil Resistance to be at 25 Ohms. However, it is always desirable to keep this value at a minimum. The tolerance values also goes down depending on the class of Electrical installation (LV, HV, EHV).

Depth of Ground Electrode

It is important to bury the Ground electrode at an adequate depth inside the ground mass. This ensure that the electrode is connected at least soil resistivity value.

The depth of ground electrode varies based on each site location and the quality of soil.

Normally the layer of soil closer to ground level has the highest resistance value which decreases as we go down deep inside the earth. Also, a rocky soil negatively impacts the soil resistance (increases it).

Due to these facts, It is usual to find ground electrodes buried at depths between 8 Feet to 10 Feet where soil resistivity could be in permissible range of 2 to 25 Ohms.

Moisture Content

Moisture content in soil helps to keep the soil resistivity value under control. A dry soil offers higher resistance than a moist soil since moisture content increases the presence of electrolytes in the soil. This in turn decreases the resistivity of the soil.

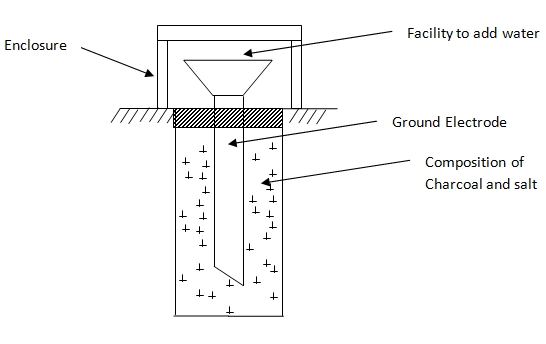

It is a customary practice to keep the ground electrode area always in a hydrated state by various external means. Normally in case of a rod type ground electrode, the opening outside the ground is provided with a funnel shaped apparatus to pour water inside.

It is also a common practice to form a circular ditch around the ground electrode rod and fill it with electrolytic material like: Rock Salt, Charcoal etc. This combination helps to prevent the moisture in the soil from getting evaporated.

See fig. below:

In some special cases where it is difficult to maintain moisture content and soil resistivity, the ground electrode and its pit is treated with chemical compound that helps to retain the moisture content and thus prevents it from getting evaporated to outside atmosphere.

Soil Temperature

Soil temperature also has some effect on the soil resistivity. Soil resistance increases with lowering temperatures of the soil. It is significantly higher in case of frozen soil areas.

Multi-Point Grounding System

In many cases where there are large facilities involved, it is common practice to use a Multi-Point Grounding System. In this type of system, an underground ground platform (grid) is built. This type of configuration establishes multiple conductive paths from various connected equipments and a common ground.

Conclusion

Irrespective of the type of grounding system, the performance of grounding system thus depends on variety of factors as discussed above. It is therefore critical that the grounding system is constantly monitored.

It is important to study the local soil conditions and soil resistivity values and also check the local applicable standards for grounding before commencing the work.

-

AuthorPosts

- You must be logged in to reply to this topic.