Hi dears! Today D.Ros gives us the next article of his article series about motors. As usual, it is very interesting ; just judge by yourself:

Since electrical motors have been around, the cornerstone of heavy duty industrial operations (as crushers, grinders, mills, hoists, blowers, chippers, mixers, compressors, centrifugal pumps, exhausters, etc.) have been driven with synchronous motors for their high power and most efficient way to convert alternating current into mechanical energy; as for, different to asynchronous (induction) motors, their main source of magnetic field is derived from direct current injection rather than through the air-gap.

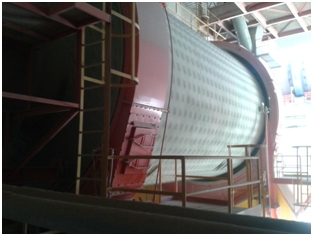

Figure 1: Ball & SAG mills powered by synchronous motors in an ore crushing operation

The high power profile (up to 134,000 HPs or 100MW) of synchronous motors addresses the increasing demand of more and faster production. As their name suggests, their run synchronously to the three phase AC lines’ frequency, however their electrical construction requires a direct current supply to generate the extra magnetic force needed in its field’s windings to overcome the natural slip produced by the armatures magnetic induction.

Figure 2: Ball & SAG mills powered by synchronous motors in an ore crushing operation

Back in the old days of synchronous motors

Typically, the field current is supplied at a constant level to ensure that the field’s magnetic poles keep locked in phase with the induced armature’s magnetic poles. This means that, depending on the application, the DC current level is set to exceed the optimal level to guarantee the motor will withstand the inherent transient demands of these high power operations.

Figure 3: Synchronous motor powering a milling operation

Disadvantages of using static field excitation level on synchronous motors

Overexciting the field windings increases the magnetic fields strength, therefore, enabling the motor to deal with a higher torque demand. However, the over-excitation of the synchronous motor’s field means that most of the time, plenty of mechanical energy is unused while the mechanical application operates in steady state, which leads to a higher energy consumption than needed and thus overheating the motors windings.

Since the mechanical energy that isn’t required is dissipated through heat, hence decreasing the resistance of the armature’s windings, which in return increases its armature’s current and in consequence, the windings heat even more; so it’s a clear looping cycle that increases electrical energy consumption and considerably cuts down the machine’s life.

Figure 4: Ball mill powered by synchronous motor in an ore crushing operation

The renaissance of synchronous motor control

In conclusion, being these machines the heart of most industrial operations, their energy consumption and downtime for maintenance is critical.

Therefore, in hand with developments of power electronics, researchers and engineers are turning their attention back to the way DC current is injected into synchronous motors: trying to find the best practices and control techniques to get the best performance of these power intensive machines by regulating the machines power profile according to its application requirements and transient conditions.

Figure 5: Oxygen compressor powered by synchronous motor

By D.Ros

Thanks D.Ros. Now what do you all think of this article?

Great and insightful article. Keep it up!

how to work synchronous motor.principle.