New article in our boxmail about SCADA systems. Here’s what you have to know about them…

Introduction

SCADA?

SCADA (Supervisory control and data acquisition) is a system that is being used in different manufacturing processes. In energetics, SCADA systems are used in substations, hydropower plants, thermal power plants, photovoltaic power plants, wind power plants etc. Thus the dispatchers can monitor the different parameters in real time (load, voltage, if a failure become etc.). They also can make different switching operations from a distance.

The SCADA systems are quite diverse, but also they have much in common. The exact definition of the concepts is quite difficult because many companies from different countries were developing these systems. But like in any other industry there are commonalities and a strong drive to unification, standardization and globalization which led to much in common both in hardware and software levels.

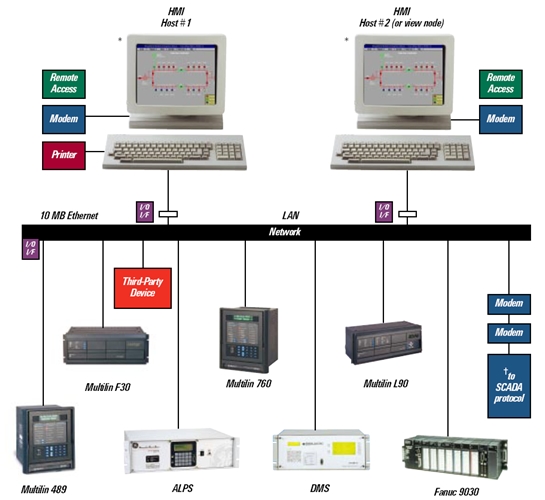

The SCADA systems may contain one or more levels. For example, a system with three levels contain at its first level, devices for connection to the sensors and the executing mechanisms. At the second level are the communication computers which may have some processing and control functions. At the third level are the operator’s workstations. These workstations are also the HMI (human machine interface). Such a system you can see at the following picture:

As you can see this is one very complex system. The three levels are as follows:

- At the bottom of the picture you can see different types of sensors, controllers, modems etc. which are installed at the substation.

- Then you can see the communication level. It can be either through direct connection of serial input/output channels or remotely through Ethernet. The serial interfaces that are supported include RS 232 and RS 485 using wire or fiber connections. The maintenance of the local area network (LAN) or the global network (WAN) is provided in the standard stack of TCP/IP.

- At the top you can see the operator’s workstations or HMI. All the data from the substation is stored there. From there, the operator can adjust the different defenses and controllers, can make different switching operations etc.

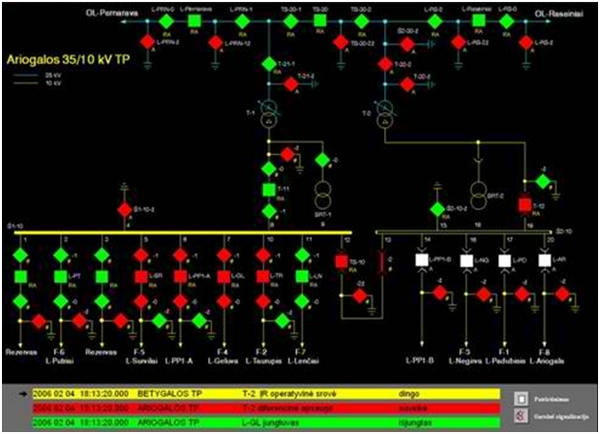

At the picture above you can see how the dispatches see a substation on their screen. As you can see it is very easy from here to monitor the whole substation and with just one click to make switching operations. Every company that is building SCADA systems has different visualization but the concept is the same.

On this screen can be visualized also:

- Operating with mnemonic diagrams. Upon opening the desired mnemonic diagram, the operator has access to the following commands: remote control, issuing commands to the selected logic controllers, changing the parameters of the logic controllers, setting the time etc. On the mnemonic diagram is visualized the online status of all technological equipment and processes, the values of voltage, active and reactive power, current, the status of the controller in LAN etc.

- Alarm pop-up window in which are written the events that came from the devices (activation of defenses, automation, crossing the limits of the monitored variables etc.) and a description of all major actions of the operator.

- Displays additional information about the selected object.

- Importing of a new configuration (adding new users in the system, changing the existing mnemonic diagrams, adding new diagrams etc.)

- Preparing reports – you can receive a data for a given time period.

Functions can be added or removed according to the user needs.

xx

In a conclusion we can say that SCADA systems are widely used in the modern power systems and they will continue to improve and integrate worldwide.

They have many advantages such as real time fault alarms, real time monitoring of all parameters, gathering the data from given substation for further analysis, remote switching operations without risk for the operating personnel, reduce overall costs etc.

An active enterprise that could reply to market styles and

execute critical choices can be sustained via a clinical understanding of GBS operating

designs as well as procedure efficiency to serve essential business features such as finance, supply chain, sales, as well as

advertising and marketing. Amount 1 reveals considerable automation capacity within commercial production, which

has greatly concentrated on certain components of Engineering R&D,

yet inadequate, when it concerns automation as well

as introduction in global shared services so far.

Their task title was: Optimization of a Production Cell at Edwards Lifesciences.