Introduction

A burnout is a drop in voltage in electrical power supply system. A burnout may be intentional or unintentional (spontaneous). Both occur in different circumstances.

Intentional burnouts are used in emergency situations when there is a requirement of load reduction.

During short-term voltage drop or fall, the reduction is for a short duration while in case of intentional burnouts, the voltage fall may extend from minutes to hours.

The reduction of light intensity during the voltage drop thus gives the name burnout to the process.

Reason for voltage reduction can either be a disturbance in electrical grid or a deliberate reduction so as to decrease the load in order to prevent a power outage or blackout.

Effects

A burnout may save an electrical apparatus from damage caused by a power load but it can also damage some devices severely.

The heat output of any resistance device is equal to the true power consumption. The output as well as the power consumption increases with the increasing voltage.

Normally, every electrical device has a maximum level of heat output till which the voltage can increase and the increase does not damage the device. But an increase in voltage past this level may damage the inner apparatus of the device causing a burnout.

Power consumption of a device is directly proportional to square of the voltage applied to that device. This implies that only a small reduction in the applied voltage will cause a substantial loss of heat output.

An example of this phenomenon is dimming of an incandescent light bulb because of a decrease in the input voltage. This happens because heat creation in the filament of the bulb drops and there is less conversion of heat energy into light.

In this case, there is no actual damage occurs to the bulb but its output is decreased.

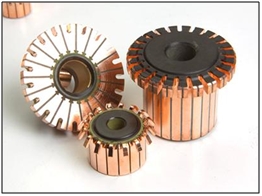

Commutated electric motors are so designed that they reduce their functionality with a decrease in the input voltage. Whether or not any harm will come to the device, because of the voltage drop, depends on its design. Under load however, reduced back-EMF develops at the lower armature speed which may cause the electric motor to draw more current.

This eventually overheats the motor leading to a burnout. It can be prevented if the motor has adequate cooling capacity, which again depends on the design of the device.

An induction motor on the other hand, compensates for the drop in voltage by drawing more current, leading to overheating of the motor and ultimately a burnout.

Electric equipment consisting of electric motors may get damaged when overload reduction is attempted, by reducing the voltage.

In electronic circuits, an unregulated direct current supply produces a diminished output voltage. This can be observed in a television when the image on the screen shrinks in size and becomes all fuzzy because of the decreased voltage output.

In case of a regulated direct current supply, the output voltage is maintained until the burnout becomes severe. Then, the drop in input voltage exceeds the drop out voltage limit for the regulator. The output voltage falls at this point and causes high levels of ripple on the output.

When the input voltage falls, a switched-mode power supply with a regulated output is affected. More current is drawn to maintain the stable output voltage and current. This increased amount of current drawn in the system damages it by the heat it produces, and leads the power supply to total malfunction.

Systems with digital control circuits exhibit unexpected behavior because of burnouts. This may not damage the circuit completely but affects its functionality. For example, a motor with such circuits can begin running backwards because of a burnout. Steps should be taken by the designer of the apparatus to prevent such unexpected behavior of a device.

Prevention

We can however prevent a device from damage because of a voltage drop. Whenever using an electrical device or system, we must ensure that the electrical equipment are running on the suitable voltage as well as correct specifications. The complete wiring of house should be checked thoroughly for any leakage in electricity.

Damaged insulations must always be repaired as they may lead to a short circuit. There are specific things that cannot be done by an amateur electrician. One should seek out expert help on such matters so that the damage could be controlled properly.

Various electrical burnout protectors are available in the market which will function well to prevent a possible burnout.

Starter switches, relay switches, Thermostats, contactors, and similar switches will not allow electrical burnouts in any condition. Copper mineral is the main element, used in the contacts of these switching mechanisms, along with ceramic or Bakelite components.

It efficiently provides protection against burnouts by making these switches able to absorb voltage variances.

To prevent burnouts with efficacy, one should keep checking for updates regularly.

What do you think about it? Do you know extra ways to prevent burnouts?