Hi folks! Check the 9 guidelines we received last week from one of the members of the Electrical Engineering Community.

Then feel free to post a comment to say if you agree or not.

Testing power cables for online power discharge (PD) has become an important aspect in the testing of power cables in the recent past.

Electric utilities are bound to perform PD tests order to ensure safe and efficient operation of the power cables.

Online PD test is normally performed using some of the following sensors:

- Current transformer with high frequency (HFCT)

- Transient earth voltage sensor (TEV)

- Coupling capacitor with high voltage

- Acoustic sensors, etc.

Note: Some of the above mentioned sensors allow online installation (i.e., can be installed while the cable is live), while installation of others need power outage.

Irrespective of the kind of sensor one might use to measure power discharge online, one should always take into consideration the following 9 important guidelines.

Guideline – 1:

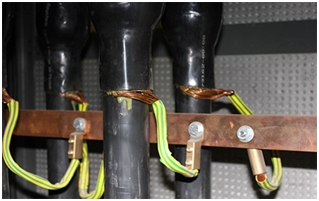

Earth shield of the cable that comes out of the cable, should not come into contact with any other metal that is earthed, except at the substation, where it gets terminated. This rule applies for both single as well as triple cored cables.

At the point where the cable terminates, shrink tubes should be used to insulate the earth shield of the cables. This will help in obtaining access to each of the earthed cables when needed in the future.

Guideline – 2:

Working at the termination points is not generally permitted when the cable is live, for safety reasons.

In order to be able to work in such situations, permanent sensors have to be placed during the initial stages of installation of ‘earth cable termination’ itself. And the sensors thus installed, must in turn be connected to a termination box, for safe operation, and testing of PD at the end of each earthed cable.

Guideline – 3:

While detecting online PD, understanding Cable Return Time (CRT) plays a vital role. CRT can be defined as the amount of time a single pulse takes to travel along the entire length of the cable that runs through the circuit.

After detecting a probable PD in a cable, CRT helps in determining the approximate location where the PD might have been taking place.

Guideline – 4:

For potential discharge test to be reliable enough, it has to be conducted for as long as possible.

Conducting this test for a longer period of time will not only help locate the points where there is a continuous discharge, but will also help locate those points that discharge intermittently.

For best results, it is highly recommended that the PD test is performed at either ends of the power cable.

Guideline – 5:

Frequencies of most PD signals that traverse along through the length of the power cable are less than 5 MHz and are not very dominant.

Hence, while filtering noise signals that have a frequency range of 100 KHz to 5 MHz, enough care should taken to see that the PD signals do not get filtered along with noise signals.

Guideline – 6:

Potential discharge signals are usually consistent in phase. However, in some cases, even noise signals are also consistent. In such cases, it can be a tedious task to differentiate between the PD signals and the noise signals.

Latest tools available in the market promise that they can differentiate between these two signals even when they are in consistent phase. Please do not rely on them. It is always good idea to use conventional methods to differentiate between the noise and PD signals, when such situations arise.

Guideline – 7:

Here are some tips to identify PD signals in such situations:

- Observe the shape of the pulse. PD pulse has generally a sharper peak when compared noise signal, and then, a few oscillations follow.

- Signals of PD are phase consistent throughout their travelling path, whereas noise signals may hamper at some instances as they travel along the circuit. Hence, conduct the noise activity measuring test, for as long as possible, in order to get accurate results.

Guideline – 8:

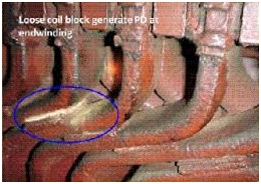

Once you have confirmed that there are PD signals in a power cable, and have located its source accurately, plan for a power outage and get the problem rectified at the earliest.

Guideline – 9:

Even after the rectification has been done, it is recommended that you keep conducting PD tests on the particular power cable circuit, for a few more weeks, just to determine if the problem has been solved permanently and professionally.

Conclusion

It is quite understandable that testing online partial discharge in power cables is quite a daunting task, but it is definitely not impossible. By using proper methodologies, instruments and by following expert guidelines, one can easily differentiate between PD and noise signals.

If one is able to discover the presence of PD signals in time and eradicate the source at the earliest, Plant owners will be able to save huge operational costs and power outages.

What do you think of these 9 guidelines. Would you remove or add one?