Benefits and applications of medium voltage according to Marvin M, one of the member of the community.

Introduction

Traditionally, any voltage over 600 V would evoke thoughts of high danger from the perceived high voltage. Engineers and technicians alike would abandon any systems operating over that limit and instead focus on the low voltage components, citing relative low risk levels.

Today, however, high skill levels, standards and installation requirements ensure that working with medium voltage is safe. It accords the following benefits.

Primary Metering

Primary metering is metering on the positive sides of the transformer. This saves a significant amount of kWh charges (about 5%). Rather than at the point of delivery, the meters are installed at the transformer, that is, the source.

In addition, the installation of the transformer has secondary benefits. Power distribution transformers with taps in the primary windings offer the primary benefit of allowing the user to regulate the secondary voltage as per the equipment ratings. This provides a closer fit with the equipment tolerances, as well as reduces chances of short circuits and arc flash incidents.

However, the engineers must first evaluate the potential energy rate savings against the cost of acquiring, installing and maintain the transformers for the primary metering application.

Fig 1: Primary metering with riser poles at a substation

Minimize Voltage Drop

Ohm’s law (V=IR) clearly stipulates the basic relationship between the voltage drop and the current. The larger the load current and conductor impedance, the larger the voltage drop. In such cases, in case the source power is low voltage with long feeder lines, the feeders tend to be oversized to cover the losses due to conductor impedance.

MV feeder lines have lower load current, thus less voltage drop. This eliminates the need for oversize conductors, thus making the system more efficient.

Cost

The cost of copper has steadily risen in the recent years. Contractors, engineers and technicians seek to reduce the amount of copper in the feeder lines and line cables in the distribution system.

A workable solution is to invest in medium voltage distribution systems. The higher voltage results to lower current, which in turn means fewer conductors to distribute the power. The lower the number of conductors, the less the amount of copper used, thereby reducing on the conduit and installation costs.

Although MV drives are more practical in most of the industrial applications, various studies seek to determine better economic solutions. Do note that, due to the higher voltages, the current is lower. This reduces on the cost of copper cables required. The cost factor is more substantial especially in cases where long feeder lines are required, and the cable size, cost and the voltage drop become significant and substantial.

Applications of Medium Voltage

Any facility or plant that demands large amounts of power utilizes medium voltage. Other than the small, medium to large plants, other typical application areas are the data centers. A typical distribution system in data centers consists of a number of transformers and generators to prevent data loss due to power outage and redundancies.

However, such systems tend to be double or triple in size with the installation of these preventive measures. Rather than accrue the high cost, most data centers relocate the transformation as close as possible to the substations, maximizing on efficiency and reducing cost. Secondly, MV voltage usage in data centers ensures scalability, adaptability and modularity.

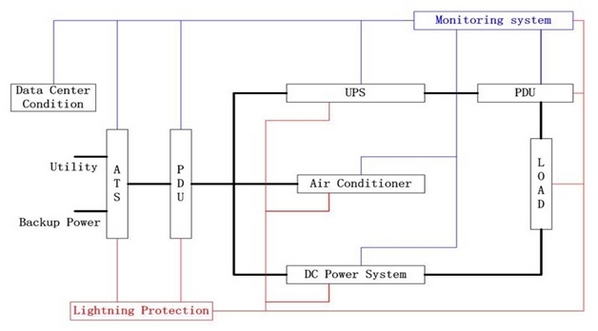

Data centers grow with technology: the power system should be set up, in a way that allows for easy and cheap expansion with minimal power interruption. With MV power trains consisting of the substation, UPS, Power Distribution Units (PDU), automatic transfer switches (ATS) and the backup generators; expansion is then easy as the only thing required is the connection of more power trains.

Fig 2: Data center power distribution system

Other applications of MV include campus type facilities with centralized chilling or generating plants. Inclusion of an MV system eliminates the need for transformation equipment in such cases. In the same vein, large footprint warehouses, and high-rise structures are good candidates for MV distribution systems, due to the potential for long feeder lines.

For the high-rise buildings, the medium voltage, due to the reduced cable size and length, consequently reduces shaft size throughout the building, thereby increasing the usable footage area.

This was Marvin M’s vision of medium voltage and the advantages of it. Now what is your opinion?

This is good concept of this article. I think this is most valuable part of electrical equipment of voltage. Every transformer is provide a proper voltage, otherwise our electrical equipment is not run properly.

Thanks for sharing this good article. I really like this.

thanks for sharing this good information . I like it.