The author of this article has 20 years experience in power installations, testing, control and maintenance. Let’s see which advices he does give us to keep it safe and effective…

Introduction

A good grounding system should provide the maximum safety from contact, electrical system faults and lightening. For a grounding system to perform efficiently over long periods of time, it should be designed and installed using reliable materials and proven techniques.

Grounding is important for 3 main reasons:

- Safety to people

- Protection of equipment and building which may come into contact with the live wires or systems

- Electrical noise reduction

The effectiveness of the grounding system depends on the individual components. Some of the factors to consider include:

- The grounding conductors: that connects noncurrent carrying metal parts to raceways, enclosures, etc

- Grounding electrodes

- Grounding Connectors

- Type of the soil and environment

Components of a building grounding system

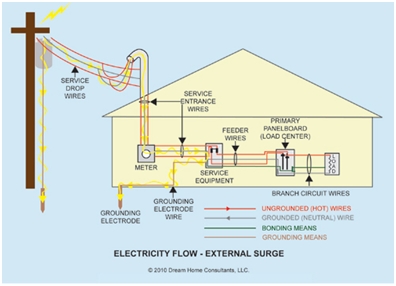

Figure 1: How grounding protects an installation against external surges

Image ashireporter.org

The electrical service ground – Ground bus

The installation inside a premises or structure should have a bus bar that provides a single point ground. This is usually a heavy copper bar or wire of low resistance and capable of carrying the total load back to the ground at the supply.

This can be extended along the length of the circuitry to ease the connection at various points.

Equipment grounding conductors

In all cases, the equipment-grounding conductor should be used and one should not rely only on the raceway system for grounding.

For any given installation, it is recommended that all the metal enclosures, boxes, equipment grounding connectors and races be bonded into one electrically continuous system. In addition, the size of the grounding conductor should be equal to that of the phase conductor.

Lightning protection

This protection consists of a lightning rod at the top of a building; it should be the highest point above the building.

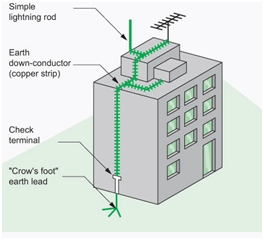

Figure 2: Ground system for lightning protection

image: Schneider Electric

The other components include the earth down-conductor such as a copper strip. This takes the current from the rod to the earth lead buried in the earth mass. The crow’s foot shaped earth element provides the connection to the ground and a check terminal is usually placed between the earth lead and the down-conductor.

Grounding electrode system

An effective system should have all metallic parts of a building bonded together and to the grounding electrode. This should include structural building steel, concrete encased electrodes, metal underground water piping, plate electrodes, ground ring, metal piping systems etc.

The grounding electrodes from different buildings should then be bonded together to create one grounding electrode system and have all the structures share a common ground.

The electrical appliances, power, telephone system, cable television should be adequately bonded to the grounding electrode through the provisions provided by the manufactures, and usually through the power socket which has a ground connection through the building and running back to the utility inlet where the grounding electrode is buried.

In addition, all indoor and outdoor metallic structures should be bonded to the ground electrode system; this includes the lighting protection down-conductors.

Ground Rods

The ground rods can be installed as close as 6 feet apart. The best practice for multiple rods is to space them at a minimum distance that is twice the length of the rod. For rocky and mountainous terrain, or other areas with poor soil condition, one should install the chemically-enhanced or deep-driven ground rods.

The ground rod is one of the major components of a grounding system. The selected rod should therefore be effective and reliable. One of the factors to consider is the type of coating on the grounding rod. The coating is based on the soil structure and should be resistant to harsh conditions such as corrosion or other surface degradation effects from the soil.

For this reason, it is important to test the soil and establish if it is corrosive, acidic, or any other quality that would affect the rod. The soil characteristics of the exact location for each rod, influences the coating to be used.

While there are many soil characteristics, the ground resistance and soil pH are the most critical. In particular, pH below 4 is usually harmful while rods in high pH soils last longer.

Ground resistance

One important parameter that should be measured is the resistance between the electrode system and the ground. This should be 25 ohms or less in most normal loads. However, the value should be about 5 ohms or lower for industrial installation with sensitive electronic loads.

The ground resistance should be checked regularly, about twice a year for the sensitive loads. This is done using the Ground resistance meters. The grounding should be checked whenever the resistance starts increasing beyond the initial values.

Soil Characteristics

The overall effectiveness of an electrical grounding is determined by the choice of materials, the technique and the soil or ground structure. The soil properties include the resistance of the earth, moisture content, stray current, soil type, mineral content, buried components, soil contaminants, dissimilar metals buried in close proximity and more.

The more moisture content, the lower the soil resistivity. Dry and arid areas may require enhancement materials to lower the soil resistivity and the system impedance.

As there are likely to be variations in most soil composition, it is important to pay attention to what type of rod coating has worked or failed at the particular place. This can be improved by paying attention to the soil resistivity and pH.

The coating alone is not enough to guarantee a sound grounding system. And one should consider all the other factors including the soil characteristics and the installation technique. The proper technique should be used to avoid damaging the coating, especially when driving the rod in rough or rocky soil.

Summary

By following good practices, the grounding system can be effective throughout the entire life of a structure, while requiring minimal maintenance. To ensure safety and long service life, the grounding system should be inspected and maintained periodically.

The right choice of materials, installation techniques as well as soil with the right characteristics provides the ideal combination for an effective grounding system.

A.N

So fellow members of the EEC blog, what do think about these advices? Do you have more good practices to add?

The picture shown does not have neutral return path, which is a statutory requirement in India. Floating neutral will result in a lot of equipment failure especially in single phase loads

Enjoyed this article, I fully agree that the grounding system should be inspected and maintained periodically in order to ensure people are safe and also to ensure a long service life.