Keeping the electrical components of a switch gear clean and contamination free is quite important for its safe and reliable operation. Here’s a nice article by your fello welectrical engineer K. who wanted to tell you about the cleaning of a MV/LV electrical equipment and switchgear. Enjoy and comment!

A contaminated switchgear

Cleaning is considered an integral part of every routine maintenance schedule of a substation and separate teams are often assigned for the purpose. Choosing the right kind of cleaning methods is necessary as the wrong methods may damage the equipment or prove to be un-economical.

There are different cleaning methods used as the routine maintenance and choice of a particular method is based on following two main factors:

- a. Nature of contamination involved

- b. Expected downtime allocated

Different tests are also conducted to check for operational abnormalities after the cleaning session right before powering up the equipment again.

Special care should be taken so as to prevent the human contact with live parts of the equipment during cleaning. It is always recommended to turn off and isolate the equipment to be cleaned and safety regulations should be given proper considerations.

Cleaning electrical equipment and switchgear: methodologies

Different methods exists based on cleaning apparatus, solvents and types of equipment to be cleaned. Let us discuss some of these.

Cleaning brushes and clothes

Cleaning rags can be used for cleaning the interior of switchgears but special care should be taken. Loose fiber may cause further contamination and result in more harm than good. Cloth rags specially designed for the cleaning of insulators and switch gear interior should be used.

A degreasing wipe

Cleaning cloth should be free of contamination and adhesive agents. Another problem with rags is their tendency to catch up on small parts and they may damage the delicate components of a switchgear trolley.

Cleaning agents

Contamination found in MV and LV switchgear trolleys are usually adhesive and solvents are often required in order to properly remove them. Special care is required when selecting a solvent for the cleaning of electrical apparatus and the solvent should be

- a. Easily removable

- b. Nonflammable

- c. Inert to the material being cleaned

- d. Not interfering with electrical/mechanical functions of the switchgear

- e. Easily dryable

- f. Environmental friendly and non-toxic

Cleaning by industrial vacuum cleaners

Industrial vacuum cleaners are good choice when it comes to the cleaning of a switchgear. However certain factors make it more suitable for the purpose which are

- a. Gentle suction

- b. Nonmetallic parts and hosing joints

- c. Its receiving hose should be designed so as not to damage the insulation if accidently hit or rubbed

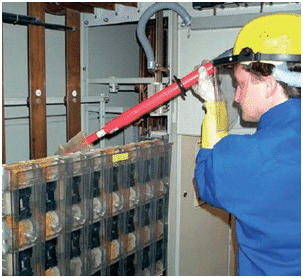

A worker is cleaning the interior of a switchgear housing

Compressed air cleaning methods are not recommended for the interior because they spread the contamination further and may push it to delicate electric parts of a substation switchgear.

Even if the traditional moping is being performed, a chemical agent should be used to limit the spread of contaminants via air.

High pressure air

This method is a bit risky and requires special training and strict safety compliance. Gas masks and personal protective equipment are necessary and staff should be trained for the purpose.

Pressure of the air should be within the limits set by safety regulations and the air should be clean and debris free. Presence of water vapors may complicate the situation and air should be as dry as possible. Even the slightest contamination in the air may badly damage the interior and electrical insulation of a switchgear.

Sand blasting

Tough parts electrical equipment such as external hard racks and doors may be cleaned with sand blasting prior to painting or re-painting. Sand blasting is a special technique and demands proper supervision and adequate training.

Improper sand blasting techniques always result in personnel and property damage and should be avoided completely. Special care should be taken as the coatings of contaminants or adhesions may contain toxic and non-biodegradable substances such as plastics, asbestos or lead oxide paints.

Small MV insulators cleaning

Insulators used for the switchgear connectors are also cleaned periodically. Washing is suitable for porcelain insulators but should always be avoided in case of composite material insulators. Gentle cleaning with wet wipes is more than enough to clean the insulators used in medium and low voltage switchyards.

Conclusion

Cleaning should be adequately performed and interior/exterior of heavy duty electrical equipment should remain clean for proper efficiency and reliability. Method of cleaning plays a vital role in outweighing the risks and minor damages incurred during the cleaning process.

Thank you for reading,

K.

What other tips can you give for a good cleaning of electrical equipment? Share below in the comments section.