An attractive tool, the thermal imaging camera is now accessible to all companies. It is for the electrician an ally that accompanies him in his missions. But to take full advantage of thermal imaging, it is required to gain a minimum of knowledge and common sense on some physics considerations, in order to make the right choice .

Since a few years, the fall in prices has put infrared thermography within the reach of electricians (currently from 1000€ excluding VAT), with tools easier to use. The control offices, the experts of thermal imaging and diagnostics, and the specialized companies are no more the only ones to handle thermograms, even though they are using the more sophisticated thermal imaging tools . There are no thermal imaging cameras dedicated to electricians, but rather tools which are more or less accurate.

Main characteristics

Cameras used by electricians, and also in the building sector, benefit for most of a protection degree type IP44 or IP54. They are protected against aggressions on the construction site and also against falls. To understand better thermal phenomena and choose your camera accordingly, let’s see what the important features are.

– Size of the matrix or sensor: the matrix, composed of pixels, is impacted by the infrared radiation passing through the optical. Entry level cameras have a matrix from 47 x 47 to 120 x 160 pixels. Some manufacturers recommend for example to electricians a minimum of 120 x 160 pixels;

– Optical: It is composed of lenses specially treated for infrared spectrum. This partly explains the cost of a camera. Main characteristic: the focal length, for example 20° x 15°. As the sensor is rectangular, the first number corresponds to the horizontal opening and the second the vertical opening. Whether you want to aim at an electrical component in a switchboard from just one step back, or aim at the entire facade of a building requires obviously a different focal length. But one must remember that a wide angle lens degrades the resolution of the camera. Is the choice fixed at buying? Yes, for some cameras equipped with a “classical” fixed lens (20°). The possibility of changing the lens or of adding an optical over the fixed lens, is an additional advantage if the operator wants to expand his field of activities. By the way, the choice of a manual focus of the sharpness permits to gain in accuracy;

– Spatial resolutions (IFOV): it results from the combination of the sensor’s characteristics and the focal length of the lens, the number of pixels permits to calculate the spatial resolution of the camera, that is to say the smallest dimension seen by a pixel. For example, a camera with a spatial resolution of 2.2 mrad (milliradian) will distinguish a detail of 2.2 mm side at 1m distance. For the same resolution, but at 50 cm distance, the visible detail will be 1.1 mm. So, the smallest is the targeted detail, the lowest must be the spatial resolution. Beyond those theoretical considerations, in practice it is usually accepted by manufacturers that a measure is correct for an object which size is 3 IFOV. For example, an IFOV of 1 mrad will certainly enable the measurement of the temperature of an object of 3 mm (at 1 meter). This coefficient avoids any partial overlap between the pixel and the surface to be measured, that would give an average temperature (of the object and its environment) not representative of the actual surface temperature of the object;

– Thermal resolution: (also called sensibility or NETD – Noise Equivalent Temperature Difference) traduces the smallest difference of temperature perceptible between 2 pixels. Entry level cameras offer a sensibility of 0,1°C. A good thermal resolution enables to conduct missions of thermal measurements in buildings even when there is a small difference between inside and ouside temperatures. For the electrician, a resolution of 0.05 to 0.1 will suffice;

– Range of temperatures: a camera is designed for use on a defined temperature range. For typical applications in building sector, a range of – 20 to + 100 ° C or even + 250 ° C is quite sufficient. Moreover, from the electrical point of view, a temperature of 100 ° C or even 80°C is already suggesting that there is a potential problem;

– Refresh frequency of the frame: This characteristic indicates the frequency of renewal of the image seen by the camera, on screen. Cameras on the market include frequencies of 9, 33 or 50 Hz. Despite an influence on the sharpness and noise, for a static shot, there is no real impact of this parameter. Some cameras are limited to 9 Hz, particularly for administrative reasons of export of materials out of United States …;

– Emissivity (e):this parameter, which value evolves between 0 and 1, is specific to the surface of the target. The emissivity tables of the main materials are well known. Of this parameter depends the accuracy of measurements. For the needs of an immediate and punctual intervention, the emissivity setting on the device seems obvious (when possible). However, for a measurement campaign, the correction could be applied retrospectively with the software tool. To compare two surface’s temperatures with different emissivity, or with reflective surfaces, it is useful to place on each of them a black mat ribbon;

– Autonomy: cameras usually have autonomy of 3 to 5 hours. However, it is good to plan buying (if it is not supplied) a second battery. This allows working intensively all day without worrying about the battery life.

The electrician who uses thermal imaging camera as a complementary tool to reveal an overheating, a phase imbalance,… can be satisfied with a camera just above the entry level with a matrix of 120 x 160 pixels, a thermal resolution from 0.05 to 0.1 and a spatial resolution able to translate the heating of a wire among others without being so far of it (watch out for minimum safety distance to be observed during an intervention in a voltage cabinet in live!).

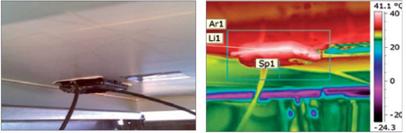

Mix between thermal and real image

Many cameras today can take a picture both in the IR spectrum and in the visible spectrum. Enough to better understand the thermogram and facilitate the formatting of the report.

Always more information

Currently, features grafted on cameras facilitate reading and counting: shooting of the actual image simultaneously with thermogram overlay, recording of audio commentary (microphone on the camera or Bluetooth earpiece) … Also appear electrical parameters measuring devices from the same brand that can, with wireless connexion, send back their measurements to the camera to incorporate them in the thermal measurement image.

“Owners” images

Maybe is this the indicator of a lack of market maturity: there is still no standard format for the radiometric image. Remember that a radiometric image provides accurate temperature value of each pixel of the matrix and permits to choose only the alert level or to highlight some characteristic points. Currently, only a software provided by the manufacturer (free with the camera or sold for more elaborated ones) allows to analyze radiometric images taken with a same brand’s camera. By the way, it is always possible to convert image files in jpeg format. But at this point, image is degraded. It is not possible to determine anymore with much detail the different levels and temperature differences.

These cameras will be so helpful for the electricians. thermal imagining will help them getting more clear views of circuits.

Could you please say more about emissivity. As i know the emissivity is a very important parameter to be understood. There are materials with composition of two different materials and i think, in inspecting such complex items, it is required to have 0.01 resolution. Do you have such options in this model?

Do you have laser pointer?

lately i had a problem using 160*120 resolution camera. I wanted to inspect the overhead transmission line, but it was not possible to get the temperature exactly. as the mean of the temperature is calculated from the background sky, and the mean is resulted as -40 degree c, on a transmission line, where the ambient temperature is 30 degree C? What could be the solution?

I have been waiting for technology like this to come available in my price range. I have cameras like this used in films etc and they are brilliant…make my work so much easier.