Photovoltaic panels are the source of energy in a solar PV system. And today we focus on how to select a module for Photovoltaic (PV) array.

If you like Solar as a topic, don’t hesitate to send us your articles or articles idea by mail.

Photovoltaic panels

Photovoltaic panels transform the solar radiation into electricity by a process known as photoionization in which incoming photons from the visible light spectrum hit the surface of the solar cells. These are composed of P-N junctions with silicon and doped with boron and phosphorus.

This structure makes it possible for a continued flow of electrons released from the silicon atoms when a photon hits the solar cell and make the electrons to pass on the conduction band.

Since they are an essential part of any PV array, it is necessary for you to know which parameters you should take into account when selecting a module considered for an specific PV array. Here we will examine these aspects.

Photovoltaic Module selection: technology

Maybe the first thing that you need to consider when thinking about choosing a solar module is the technology type.

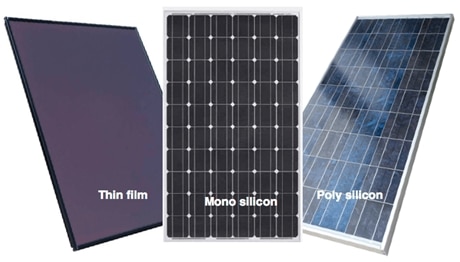

Solar modules manufacturing has evolved amazingly in the last decade, making it a wide available market with new technology developments every year. The basic and well-proved technologies are: polycrystalline, monocrystalline and thin films.

Polycrystalline panels are the oldest modules in the market, they are also the cheapest and the less efficient as well. Typical efficiencies for these modules are between 13-17 % and have a lifespan of 23-27 years.

Monocrystalline modules are the high efficient panels of the market (18-24%) and are the most expensive as well. Their lifespan is between 25-35 years.

Thin-film technologies are the most recent panel types in the market and they are usually applied for building integrated purposes, they are cheaper than monocrystalline but more expensive than polycrystalline and have efficiencies between 7-14%.

IMG Fig1. Types of Solar Panels | image: cleanenergyreviews.info

Photovoltaic Module selection: sizing

To make your technology selection, you must first be aware of several considerations.

PV modules have standard power ratings and so in order to determine the amount of modules to be connected you must first establish the load that you want to feed in kW.

After that you must choose a system type configuration between grid-tied, hybrid or off-grid system according to your needs. Once this decision is covered, you can proceed to the technical aspects of modules selection.

Voltage

As you know connecting modules in series would lead to higher voltages. Inverters have a range of voltage for MPPT (maximum power point tracking).

You have to make sure that the operating voltage of you array (at 20°C and 60°C of temperature module) will be within the MPPT range of the inverter.

Besides, there is another limitation in the voltage of the array, each string cannot exceed 600 Vdc according to American norms and 1000 Vdc according to European norms.

Fig2. Maximum Power Point Tracking Ranges | image: Handbook of Photovoltaic Science and Engineering

NOCT and STC

As a reference to compare performances of PV modules, manufacturers establish the so-called Standard Test Conditions (STC) and Nominal Operating Cell Temperature (NOCT) which have specific test conditions that allow you to compare the virtues of each module between them.

STC assume 1kW/m2, 25°C of module operating temperature and 1.5 AM (Air Mass), while NOCT assume 800W/m2, 45°C operating temperature, 1m/s wind speed, 20°C ambient temperature and that the module has a ground mounted feature (for air circulation). Under these conditions you must evaluate:

- Open circuit voltage

- Short circuit current

- Nominal power and current

- Voltage and power at MPP

Efficiency

Crucial parameter to size your system, among each type of technology there are also variations in efficiency.

This parameter is associated with the use of available space in m2 to supply the same amount of power. In other words, the higher your efficiency, the smaller your panel is to provide the same amount of DC power

Photovoltaic Module selection: temperature coefficients

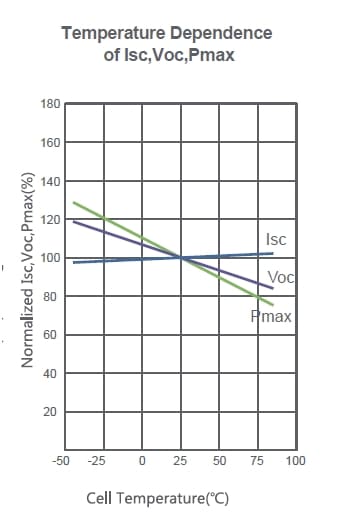

Rising temperature values affect the performance of PV modules, they reduce the efficiency, voltage and current as well.

Although current temperature coefficients are generally provided in the datasheet, the most important ones are the voltage and efficiency temperature coefficients, as voltage is severely affected with elevated temperature values.

You need to select the modules with the lowest voltage temperature coefficient as shown in the picture below.

Fig3. Temperature Variation vs Short-circuit current, Open-circuit voltage and maximum power of a 350 W Jinkosolar Panel | image: jinkosolar.com

Tolerance

Manufacturing processes are not perfect. That is why manufacturers will provide a tolerance value for the nominal power output of the module. The less the tolerance is, the more accurate your design will be.

Solar panel Dimension

Finally, the ultimate consideration is to watch out for the panels dimensions, you must make sure that the width and length of the panel, suits your available space, whether it is on the roof or on the ground.

Considering all these factors will reduce the chances that you need to change your module selection, nevertheless, sometimes you will need to iterate several solutions according to space, inverter selection and power demand.

What do you think about Solar module slection? Did this article help?