Most probably, if you are an electrical engineer, you know what MCC stands for. So let’s briefly introduce it to those who are not experienced in this field.

MCC stands for “Motor Control Center” and as you can grasp from its name that it is used to control motors in the industrial or even commercial applications where many motors are to be controlled.

The questions now are why do we use MCCs? And what are the components?

Motor control centers: why do we use them?

If we have large industrial area where many electrical motors are used these motors need to be protected from abnormal conditions and/or any overload. But controlling and monitoring the operation of each motor from the field requires hundreds of controllers and control panels.

However monitor and control is always done from the electrical central room, therefore an Motor control center is located in that room and electrical signals are sent to the motors in fields.

Motor control centers: what are the components?

There are many common components among all types of MCCs and some special components that depends on the application.

The common components include:

- Circuit breakers or fuses: We have already discussed the usage of those devices in other articles, but briefly they are used for protection from faults. The used circuit breakers types shall be as follows:

- Circuit breakers feeding loads up to 0.75kW shall be of the miniature type.

- Circuit breakers feeding loads 1-7.5kW shall be of the Manual Motor Starter or Motor Circuit Breaker type.

- Circuit breakers feeding loads greater than 7.5kW shall be of the Moulded case type.

- Push Buttons and Selector Switches: They are used for start stop operation of the motor either manual or automatic.

- Indicator lamps: They are used to show the status of operation whether it is start, stop or fault.

- Digital Multi-meter: To measure voltage, current and frequency.

As many other components that differ according to the type of MCC are used. Let’s first discuss the types of MCCs.

Types of MCCs

There are many applications where MCCs are used. However the most common applications are MCC of HVAC systems and MCC of Fire Fighting Systems.

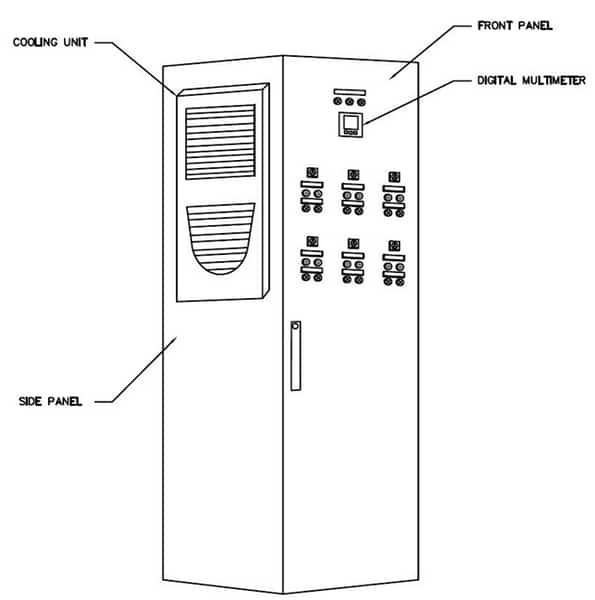

Figure.2 Typical MCC Panel | image: safvolt.com

In HVAC systems there are many components in the system that are motorized like cooling tower, heating tower, smoke dumpers, fresh air dampers and all fans.

In Fire Fighting systems the motorized component is the pump used in pumping water to the location of fire.

In the above applications there are other components that are added to the MCC in addition to the common components like relays and contactors for star/delta operation of motors, soft starters or variable speed drives. Using any of them depends on the scale of project or in other words the rating of motors used.

Motor starters types shall be as follows:

- Motors up to 0.75kW, 220V, D.O.L.

- Motors 0.75kW – 5.5kW, 380V, D.O.L.

- Motors 7.5 kW to 45 kW, 380V, Star Delta

- Motors > 45 kW Soft Starter:

• The soft starter must be equipped with the following features:

• Phase sequence

• Phase loss

• Over current

• RS-232 Serial Interface (Modbus RTU)

I have explained many of the standards used in designing an MCC, but of course there are many things to be considered too. Maybe I’ll explain them in other articles. For now, I hope you enjoyed it.

Steven Mill.