Michel, a french member of the community sent us this article, and we tought it was interesting for you to read it and give your impressions.

By the way, we all thank you for sharing knowledge with the Electrical engineering community. If you haven’t shared yet, you still can send us a mail.

Inserted into ventilation and air renewal systems in the buildings, the speed variator can deliver the right air flow in real time. Some considerable assets in terms of energy performance and maintenance equipments.

In addition to the use of electric motors at high-yield, the speed variator contribute to the reducing of energy consumption. Concerning the business buildings – service sector ones, and also the industrial buildings, two main categories of application are targeted. First, ventilation and then, domestic water pumping, notably in tall buildings or skyscrapers.

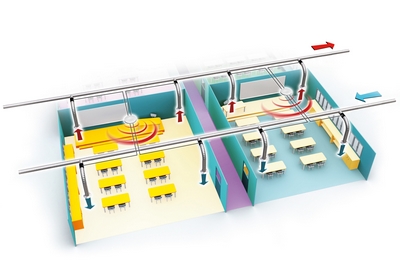

The effective management of the source of new air room by room, requires the setting up of a speed variator. Photo Credits : ATLANTIC.

Adjusting flows to reduce consumption

Of course, depending on the way the premises are occupied, the needs vary and it’s not necessary to constantly deliver an air flow or a nominal pressure. Today, this logic of energy performance is backed up with three facts – the increasing costs of energy, the national thermal regulations more and more severe and the decreasing costs of the electronic equipments made for piloting.

Let’s remember that electric energy consumed by pumps, fans and compressors represents a significant part of the electric energy consumption around the world. In the industrial process and the building trade, more than 70% of electricity is consumed by motors and more than 60% of its energy is used for the stream of fluids.

HVAC, variable flow for a constant comfort

The speed variation in air treatment plants is known for a long time. Its debuts were arduous at times in terms of regulation, but today the solutions are finalized.

Yet, the way the flow varies impacts on the stand-alone ventilation solutions or coupled with an air preheating/pre-cooling. The idea consists in measuring the way each room is occupied to adapt the air renewal flow necessary and sufficient for each air vent. Upstream from the air vent, one or several variable-speed motors carries out the variation of the air flow. Some systems works at constant pressure in the air duct, some much more elaborated systems compile in real time the air blowing needs of each air vent in order to give a speed set point to the variator. The speed variator remains the masterpiece of the planting, linked with the electronic of regulation. To know how occupied a room is, a detector warns of the presence or concentration of CO2 thanks to a signal from which the modulation could occur.

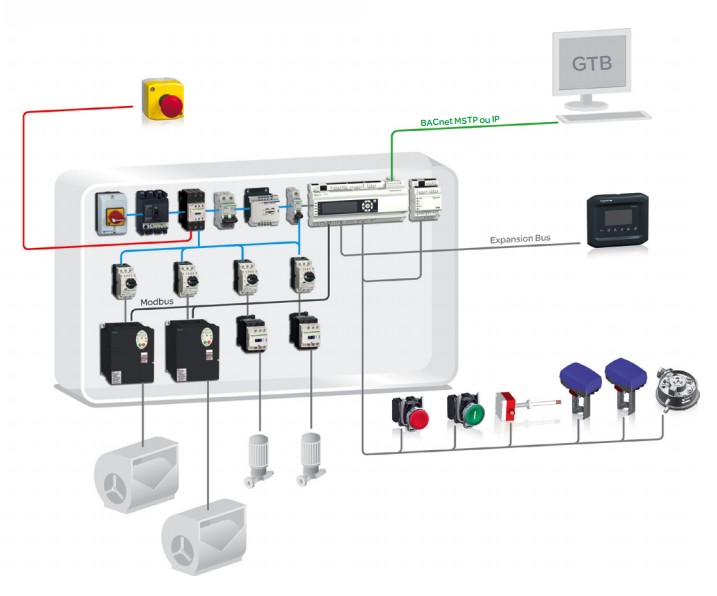

Schneider offers tested, documented and validated solutions for the HVAC sector and ventilation, which incorporate speed variation and intelligent control. Photo-01 / Credits : SCHNEIDER ELECTRIC

Indirect benefits

In most cases, without any variator, fans are sized for a maximal flow greater than the useful one. In that particular case, registers are installed to reduce the air or speed flow when they quit the circuit. Then these registers are adjusted during the commissioning of the installation. As a result, a loss of charge which harms energetic efficiency is noticed.

Yet, indirect benefits spring from the integration of the speed variation. Optimized, the flows lower to the nominal flow will permit to reduce the sounding level of the installation.

Moreover, in some cases, the abundance of the in-rush flows permits to reduce the parts of air ducts. To finish, running an equipment low-speed permits to extend the maintenance intervals for the most fragile items like bearings, pulleys, belts…and motors.

The ACH 550 variator if ABB incorporates a function which optimizes the flow to regulate according to the real charge. The aim is to reduce the energy consumption and the level of noisy data in the installations. The variator also incorporates two independent PID controllers. For instance, they’re used to maintain a static pressure in ducts and to control an external device like a cold water faucet. Photo Credits : ABB

I just wanted to say thank you for sharing a great information and useful. it really necessary and timely for me at this time. I’ve read a lot of blogs and visit but they made me feel boring.