The electric ball valve is used in different industrial applications, including water treatment plants and oil refineries. You can also use it to control the flow of gases or liquids within a pipeline system. This guide will cover all you need to know about installing an electric ball valve : from planning and preparation to the technicalities involved.

The installation process can be simple or complex, depending on your experience level and your type of system. Typically, the installation procedure for each electric ball valve varies, so it’s important to carefully read the included documentation and verify that the valve is suitable and safe for your application. The installation tips we have highlighted are specific to the BW series of electric ball valves made by JP Fluid Control but may also apply to other models in the market.

What is a Ball Valve?

Ball valves are typically used in industrial settings as shut-off valves. They can also be used on home plumbing systems, including dishwashers and washing machines. Ball valves come with a small sphere (with an orifice/opening) in the center of the valve that moves as you rotate the handle. By moving the handle, you change how much of the opening is covered by the sphere. This then changes how much liquid flows through the opening.

Ball valves are used in various applications, including water, wastewater and compressed air systems. They are simple to operate, reliable and can last for many years. These valves can be operated manually using hand wheels or automatically using electric motors or pneumatics. Your ideal choice of ball valve will depend on your unique applications and system requirements,

Electric Ball Valve Piping System

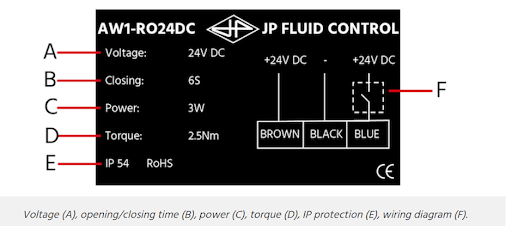

Before you begin the installation, ensure that the valve specifications on the actuator match the application requirements. Here’s an example of the valve with labels explaining the different parameters you should consider.

Once you have confirmed that the valve is ideal for your applications, you should keep the following in mind:

- The AW series actuators are splashproof, not water-proof, and hence not suitable for severe weather conditions. You should therefore install these valves in dry or sheltered areas.

- Ensure that the piping has cooled down before you begin the installation.

- While ball valves are less sensitive to small debris and dirt, cleaning the pipes is still advisable to ensure optimal operation.

- Use Loxeal or Teflon tape to seal the pipe thread. This ensures that the sealant doesn’t enter the valve as it can cause blockage.

- Choose the right fittings between the pipes and the valve. Only exert the necessary force on the designated areas of the valve (not on the actuator) to avoid stress and potential damage to the pipe or valve. Ensure the pipe has been fixed securely on a frame or wall to avoid vibrations in the piping system.

How to Position an Electric Ball Valve

Here are some tips to help you position the valve correctly during installation:

- Fasten the valves to the piping system using the right fitting. Use a wrench for the pipe and valve while tightening, and ensure there’s no unnecessary stress on both parts.

- Install the electric ball valve with the actuator facing up at a Max deviation of 90 degrees. This ensures that the actuator doesn’t collect moisture.

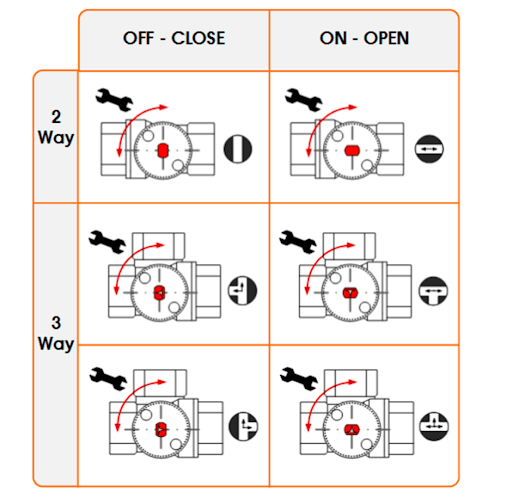

- Ensure the ball is set at the correct angle. 2-way valves open and close in a standard-operating position, while 3-way valves can be configured (in two ways) by rotating the ball at a 180-degree angle. The image below illustrates these configurations.

Ensure that the ball position in the valve is adjusted properly, such that the actuator fits on the valve. You can tighten the nut on the actuator using your hand.

Electric Ball Valve Wiring Diagram

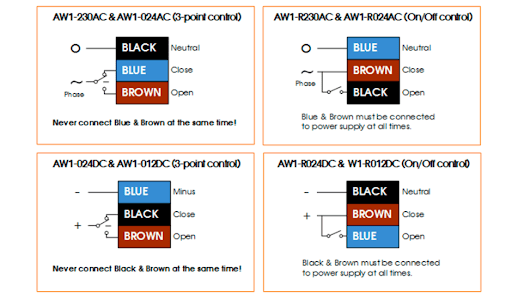

Actuators come with varying specifications, and their wiring diagrams will always vary. You can damage your actuator if you connect the wires inappropriately or use the wrong voltage. Here are the other things to keep in mind about electric ball valves and their wiring diagrams:

- You cannot change the actuators’ rotational direction by reversing the control wire’s polarity. This feature isn’t built into these actuators and shouldn’t be confused with DC motors

. - Actuators come with two end switches, which only use energy during opening or closing.

- AW1 actuators designed by JP Fluid Control are controlled electrically. That means the actuator doesn’t have a spring or mechanically-operated parts.

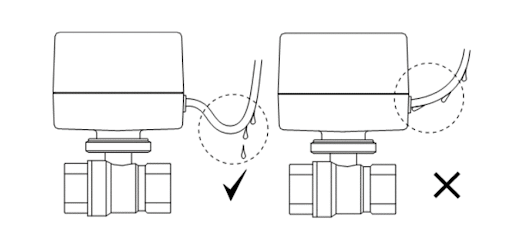

- While installing the valve, ensure that any drops won’t slip along the cable and accidentally enter the actuator.

Choose Your Electric Ball Valve

When selecting an electric ball valve to use in your system, always pay attention to your unique needs and industry standards, if any. You can also consult a trusted professional to avoid possible selection mistakes.