Home › Electrical Engineering Forum › General Discussion › Uses and applications of Vacuum Reclosers

- This topic has 0 replies, 1 voice, and was last updated 9 years, 8 months ago by

admin.

-

AuthorPosts

-

2015/03/09 at 12:06 pm #11233

admin

KeymasterHere’s another article by Martin M., one of the members who sent us the greatest number of articles. You too can send articles about whatever you want, just send us a mail

Introduction

There is a distinct difference between a recloser and a circuit breaker. The circuit breaker breaks the circuit in case of a fault. It requires manual reset. The recloser on the other hand momentarily closes a circuit in case of a fault, and then automatically restores service after the fault clears. Do note that majority of line faults clear automatically after a short period. A recloser thus offers two primary benefits.

For starters, it prevents the minor transient short circuits, such as a tree branch touching the cables in strong windy conditions, or overheads cables making contact due to wind gusts, from triggering long power outages. Through the short disconnection and restoration after the fault clears, a recloser accords power supply continuity. Secondly, as mentioned, majority of line faults are minor short circuit issues. Some of these faults occur in remote and offsite locations.With the recloser automatically breaking and restoring power, there is no need for an engineer to attend to the matter. The major recloser categories include hydraulic, magnetic, electronic, oil, vacuum, and various combinations of the above.

Today we focus on the vacuum recloser.

Operation

One of the main challenges for recloser designs is arc flashing. In the event that the contacts have been successfully separated after a fault, due to the proximity of the contacts, arc flashing can occur due to the voltage in the system. The arc between the contacts thus completes the circuit, cancelling out the initial circuit breaking action.

In a vacuum recloser, the vacuum acts as the primary arc quencher (vacuum has eight times greater dielectric strength than air, and 4 times more than SF6 gas) for use in low and medium voltage applications. For further arc quenching, and contact longevity, the contact material is an important consideration. The ideal material is CuCr (Copper Chromium composite) as it reduces the creation of hot spots, which may lead to arcing between the contacts.

To maintain the integrity of the vacuum, the unit is enclosed in a gas-tight unit, usually ceramic, and low permeability metals.

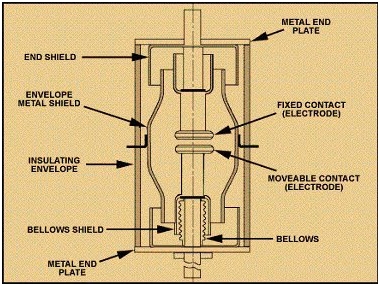

The two contacts, one fixed, and the other movable, are enclosed in a gas tight unit. There are metal bellows on the movable contacts side. The contacts are separated either through mechanical or magnetic actuator.

The vacuum prevents arc flashing, thus ensuring that the circuit remains open. In a magnetic actuator, when a fault occurs, a controlled pulse of current is released through the solenoid. This turns an included trip bar by attracting the trip bar armature. The movable contact moves away from the fixed contact, thus breaking the circuit.

For recloser, the included storage capacitor or battery, or a low voltage power supply from utility transformer sends a controlled pulse of current through the solenoid.

Alternately, the actuator, for contact separation contains an integrated spring assembly, for release once the fault is fixed. The separate power supply allows for an independent power supply for dead line operation. This closes the circuit, thus restoring power supply.

Do note that the number and duration of reclosing can be manually set (usually three to four reclosers before final lockout). This prevents the aggravation of seemingly minor faults. When the fault is sorted out, the pulse de-energises the solenoid.

Benefits

The primary benefit of a vacuum recloser is that they require virtually no time to recover (usually takes between 100-300msec for a reclosing operation). This reduces the power outage time, thus allowing for power supply continuity. Secondly, the vacuum working principle reduces on the moving parts in the equipment. This ensures longevity, as well as lower maintenance requirements. Thirdly, the vacuum reclosers are environmentally friendly as the unit is oil and gas free.

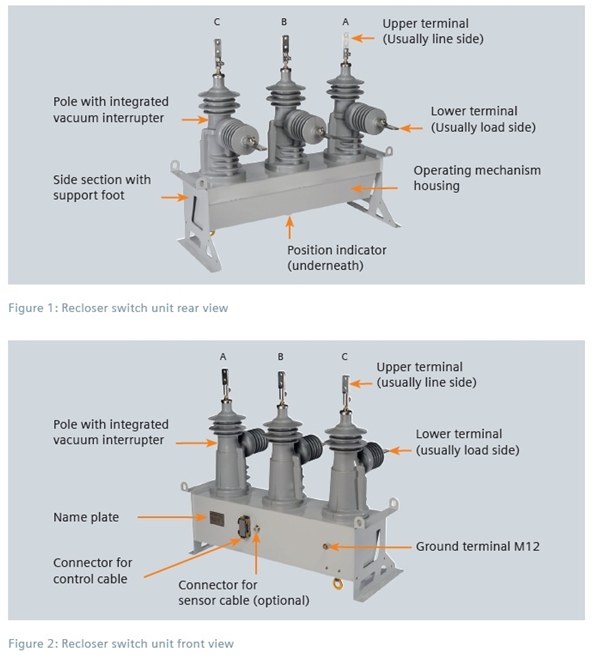

Recent innovations in vacuum interrupter technology include inclusion of a microprocessor for measuring, controlling, and remote control. This offers additional instantaneous tripping, delayed tripping and over-current protection, as well as an allocation to set tripping time, reclosing time and frequency.

Thanks for reading!

Martin M.

What did you all think about this article?

-

AuthorPosts

- You must be logged in to reply to this topic.