Home › Electrical Engineering Forum › General Discussion › Low Voltage AC drives – their characteristics & their applications

- This topic has 0 replies, 1 voice, and was last updated 10 years, 4 months ago by

Steven Mill.

-

AuthorPosts

-

2014/08/25 at 2:05 pm #11188

Steven Mill

ParticipantHello, it’s Steven Mill! What do you know about LV AC drives? Let me tell a few words about it…

What are AC Drives?

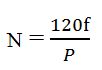

There are adjustable speed drives that control the speed of DC and AC motors. The speed of an AC motor is determined mostly by two factors i.e. the frequency applied and the number of poles. So the formula goes as:

Where:

- N = RPM

- F = frequency

- P = no. of poles

In some AC motors, there are built-in features that change the speed but in most cases the number of poles is constant and the only way to alter the speed is to change the frequency applied. So, changing this frequency is the main function of an AC drive. But it is important to note that the impedance of a motor is determined by the inductive reactance of the windings. See the equation below:Where:

- XL = inductive reactance in Ohms

- F = Line frequency

- L = inductance

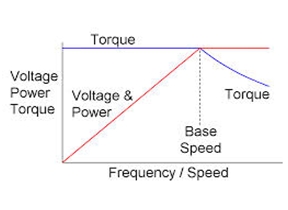

It means that if the frequency applied to the motor is reduced, the reactance and impedance is decreased. So, in this situation where frequency is reduced, lower voltage is applied to the motor to keep the current under control. The phrase “volts per hertz” refers to this situation.

Most commonly, pulse width modulated (PWM) technique is used to control the applied frequency and voltage. In this method, DC voltage is applied to the motor windings in time controlled pulses for achieving current that approaches a sine wave of desired frequency.

The latest technology that helps in switching PWM pulses very fast i.e. numerous thousand pulses in one cycle of applied motor frequency are Isolated Gate Bipolar Transistors (IGBTs). More pulses in one cycle means smoother current waveform and also better performance of the motor.

Main Features of Low Voltage AC Drives

Low voltage AC drives are basically used for adjusting the speed and torque of standard AC motors. Along with induction motors, AC drives replace the use of DC and slip-ring motors together with their control systems. Their main use is in industries because of the following characteristics:

- Soft starting and reversing of motor

- Variable as well as accurate speed control

- Dynamic torque regulation

- High power factor

- Flexible user interface

- High efficiency

These are the main features but variable and additional features are incorporated according to the machinery it is used in and also according to the need. The use of low voltage AC drives has many advantages such as:

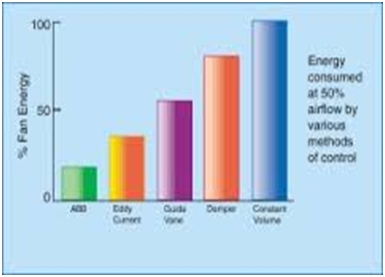

- Less energy consumption

- Increased productivity and output

- Minimal mechanical wear of the equipment

- High process quality and reliability

- Less investment in electrical network compensation devices and sophisticated electronic control

- Better efficiency of process equipment

- Very less risk of damage to the electricity supply system

Less energy consumption means that the productivity cost is reduced. As industry uses energy intensive machinery, low voltage AC drives help to achieve high frequency and better machinery performance at low voltage. This feature extends its application to a number of industrial appliances and machinery. AC drives, because of their energy efficiency, makes the machinery more environment friendly especially in mining industry.

Another important feature is that it adjusts the speed according to the need. This is very important in all industries and especially in construction, gas and oil and mining industries where a lot of drilling is required. So, hydraulic and pneumatic drilling systems are replaced because energy use is considerably adjusted according to the speed.

Desired performance is achieved even at low voltage but this does not mean that the machinery wears quickly. It requires minimal maintenance. In hard core industries, huge mechanical stress damages the machinery but this problem is solved by low voltage AC drive because it controls the speed and torque of the motor.

Applications

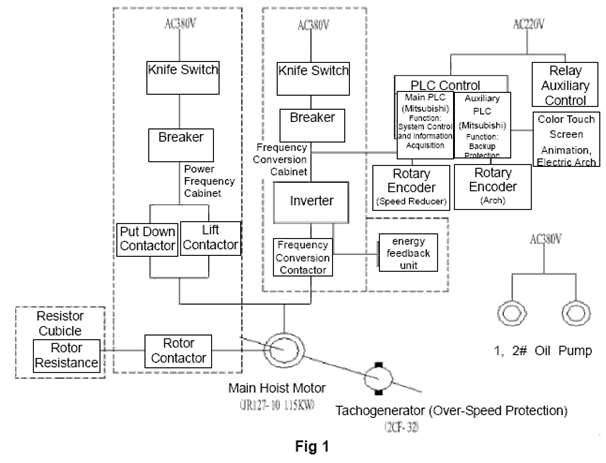

There is a wide range of applications for low voltage AC drives in almost all sorts of industrial machinery where high performance and varying speed is required but not at a huge power cost. These include machinery involved in material handling such as belt conveyor, crane, hoist, diverter, compressor, pump etc.

They are also used in textile industry in machinery like palletizer, pumps and compressors (same as in material handling) and some other machines. A major use is in mining industry where a lot of drilling, digging and crushing is required.

Low voltage AC drives are used in ball mill, rotary kiln, pumps etc. in the mining industry. Other applications include machines involved in automotive, oil and gas, rubber and plastics, construction, water/waste water, paper and pulp and even food and beverages.

Conclusion

The use of low voltage AC drives is inevitable for industrial use. This not only saves energy but also makes high end performance and huge output possible. The only primal feature of controlling and adjusting speed makes it so much useful.

What more can you say about the subject?

Steven Mill. -

AuthorPosts

- You must be logged in to reply to this topic.