The increase in energy costs has raised awareness to all stakeholders of buildings that operating expenses could be a source of economy. If the approach has been taken into account in the design, it remains improvable in the exploitation phase. It is necessary to consider the building as a process, analyze the flow and can be interesting to look at the automation experience of manufacturers in order to copy their methods and analysis tools. We also call this field, Building Management System. We propose here to address the subject from this angle.

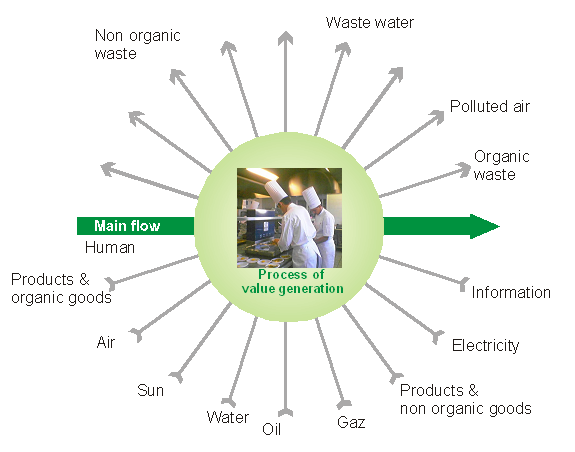

For example, a restaurant, the main flow is the one represented by the clients ; for satisfying and retaining them, the restaurant must provide a service to these clients at a certain price they are willing to pay.

This service, this value, will also correspond to several other flows, the following figure gives a schematic overview.

Each flow is characterized by three dimensions:

-

Logistics, including the concept of stock

-

Economics as the costs and investments

-

The risks to people, the environment and hazards

To make his business profitable, the restaurant must optimize all these flows. In general, designers analyze them independently and apply a process of improvement that is:

-

Measuring the parameters of the flow. This is a common approach in the management of food and goods ; It is less common for all other flows (wastewater? Discharges into the atmosphere? Power consumption by receiver?)

-

Analyze information. The IT tools do offer opportunities for processing and storage to facilitate decision making.

-

Optimize the overall process and its various components. This is done by influencing human behavior and the introduction of automation.

More complex, the overall analysis of these flows and their interaction (systemic analysis) may identify tracks for improving the efficiency of the process.

Then this approach will facilitate the introduction of automation for its functioning. At this stage we could expect to use tools based on new algorithms such as signature analysis or predictive analysis.

I would be interested to share with designers who have already thought or implemented this type of approach

my own background is more in the industrial automatism engineering

Jean-Louis Joyeux

Thanks for the useful info. It’s so interesting

Hi,

This method is one of the best example and thanks for the information, I would like to use the same methodology with different process.

It’s very true that automation and process is more important and more beneficial than going for short terms energy saving solutions. More and more companies are jumping into energy saving techniques and tips but sometimes dont realise that sometimes re-planning the chain/process could be much more beneficial and energy saving. Great post!

It is undeniable that the cost for maintaining energy in any industry is rising at a fast rate. At times like these, the best solution would be to improve work efficiency which means we should work smarter, not harder. Automation would be risky, but still worth a shot. You just have to make sure that you get involved as much as you can to the development of the system.

Fred Homes

architect Tucson