H. is a fresh graduate from Dubai. Read her review about how to improve Power Factor. She gives you 3 ways to do it and it’s a nice back to basics type of article. Enjoy!

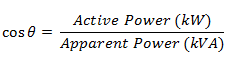

Power factor is a very common term in electrical applications because it determines the efficiency of an electrical system. It is a word that you will only hear when dealing with AC circuits as shown by its simple formula:

It is quite important that the power factor remains close to unity because it indicates higher efficiency of the system. So, today we will discuss the 3 different ways to improve the power factor which are widely used in industrial systems:

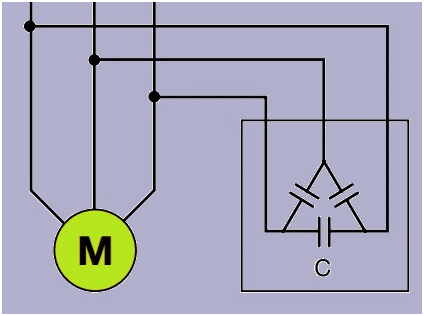

Static Capacitors

One famous factor that decreases the power factor is the lagging current present due to inductive loads. In order to improve the power factor, static capacitors are installed parallel to the equipment running on low power factor. The leading current drawn by such capacitors neutralizes or corrects the lagging reactive component of the load current.

The static capacitors have many advantages since they are lightweight, easy to install, have low losses and require lesser maintenance. However, the disadvantages are quite notable where if the voltage is exceeded then the capacitors will be damaged quickly and their repair would be costly. They also have a shorter service life (8-10 years).

Synchronous Condenser

Another way to improve the power factor is to use a 3 phase synchronous motor which is over excited and runs on no load. This setup is known as the synchronous condenser. The interesting part is that the synchronous motor can operate under leading, lagging or unity power factor. If there is an inductive load present, then the condenser will be connected to the side of the load and will act as a capacitor to correct the power factor.

The synchronous condenser has many advantages since it requires low maintenance, can run for up to 25 years and is not affected by harmonics. However, its disadvantages include the high maintenance, cost and noise. It also requires an additional equipment to start the motor as it has no self-starting torque.

Phase Advancer

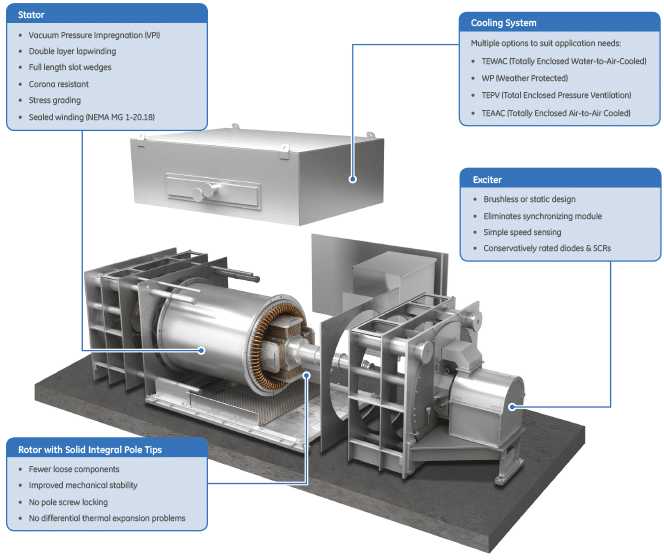

The last method that helps improve power factor is by using an AC exciter also known as a phase advancer. However, this can only be used for induction motors because the stator windings of the motor draw current that lags 90° behind the voltage and results in low power factor. The only way to get rid of this problem would be to use an external source that would provide exciting ampere-turns.

image: sourcingelectricals.com

The phase advancer helps in solving the problem when it is connected to the rotor circuit of the motor. The exciting ampere-turns provided by the advancer are at the slip frequency. A leading power factor can also be obtained by providing more ampere-turns.

The main advantage of using a phase advancer includes reduced amount of reactive power drawn by the motor. It can also be used in places where a synchronous condenser is unacceptable. However, the phase advancer cannot be used for motors below 200 H.P. which is uneconomical.

Conclusion

These are the most important and useful methods to improve the power factor but there are many other methods available in the market. If you have any other method that you would like to share, then do let us know in the comments section!