Today, K. wanted to share his associate and good friend’s experience in panel designing. This friend works at national transmission and dispatch company and few interesting things came out this experience.

Read this story below and if you want to share your electrical engineer stories too, please send a mail.

Panel designing and related safety protocols (introduction)

Beset by electrically initiated fires, this supermarket chain had decided to benefit from the services of a professional electrical engineer. My friend and associate was hired to inspect and redesign LT panels at five outlets of this chain.

It was the first time that the management had ever thought of upgrading their electrical installations in compliance with international standards, and the challenge was about to unfold itself to be of a bigger quantum than expected.

Electrical panel designing: a look inside portfolio

Tracing back the wiring from power company inlet to the main panel, main panel to back-up gen-set, and from main panel to layman end switchboards. It appears more like solving a puzzle. You get some clues by looking at the circuit breaker, its rating, and the accompanying conductor size. Tracing the main power cables is the easiest of all, as there are only two or three sets of such wiring, and everyone knows where these are coming from.

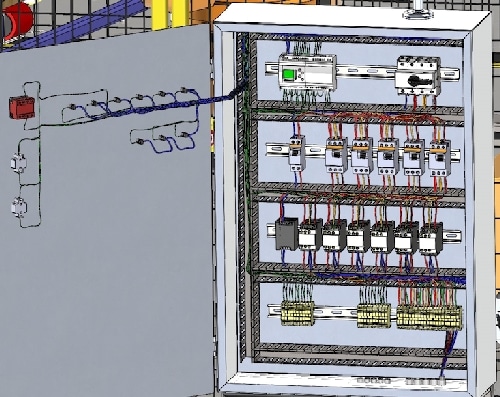

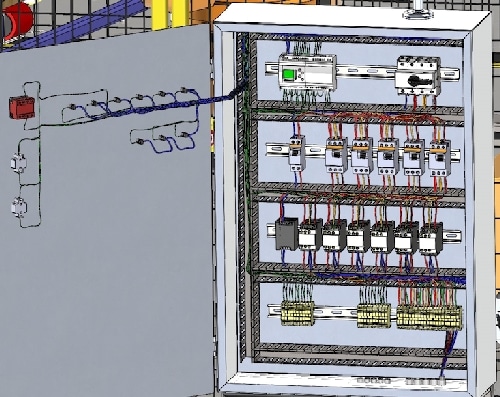

panel protection | image: shutterstock

Comedy starts when it comes down to tracing the MCBs, connected to bus bar at one end, and a 2.5mm square cable at the other. Now these cables are everywhere and no local crew can tell you for sure, which operates what. You ask your boss for help, and he suggests the primitive trial and error method.

Imagine you are there at the crockery section of this store, trying to understand this panel, and are instructed to test each and every switch. Families are also there for their routine groceries, claiming a good part of your attention every now and then. You try the first switch, and the next moment, you are sitting in sheer darkness with a panicking crowd all around.

Though you try to undo it immediately, but these two seconds were enough to cause various non-lethal accidents. To reduce the awkwardness, you start drawing the circuit on your note pad, and associate the 1st MCB you have encountered with lights.

Only after the moment of panic and darkness, you realize the hazards this place has to offer. You note down all the possible hazardous things like the quality of panel, its location, installation mistakes, and the absence of proper grounding.

You draw sketches for each and every panel, as a raw form of single line diagram (SLDs) for this building. Later on, in the comfort of your workplace, you redraw these SLDs using some computer aided drawing software.

Technicalities

Now comes the design phase where you have to suggest the right equipment and required procedures, including circuit breakers and different levels of safety standards, cable size, backup systems, grounding system, and the systems to deal with emergencies.

Panel design and circuitry

The hard work that you have done during personally inspecting all the panels is about to come handy. You have already estimated the total load and its breakups. You put these values into load calculating software and get a gist of what is required. To be sure about your suggestions your boss tells you to do a manual calculation.

These calculations tell you the exact size of cables required, and depending upon the current these cables are going to carry, appropriate protection devices are in view. At this time you consult the vendors, select the equipments, update the SLDs, and contact the client.

You should be proud of yourself, as you have contributed towards making the world a safer place.

How exactly is a distribution LV panel designed?

Panel designing takes a lot of consideration with respect to different variables a panel will be dealing with. A good amount of consideration and though process is needed when selecting suitable components. A required number of electrical circuits originate and a panel should always be designed keeping in view full load and full expected uptime for any given conditions.

Circuit scheme

All the circuits (incoming/outgoing) should be connected to proper bus scheme to avoid any future hotspot(s). Copper or aluminum strips should be deployed as and when necessary. Grounding and subsequent protection acts like nervous system of a panel and demands a designer’s proper attention. Grounding quality should come up to local electrical rules and regulations.

Power demands

Power outlets against every circuit should be proper and according to the load demands. End circuit fuses are part and parcel of a reliable panel-protection plan. Panel should be capable of handling overload/trip conditions nondestructively as far as possible.

Physical design

Physical design to be incorporated must comply with NEMA codes, installation location (indoor/outdoor/industrial site), identification of all lines connected with proper indicators for every phase and insulation criteria.

Electric Power Distribution Handbook, Second Edition by Thomas Allen Short is recommended for further study.

Thank you for reading me.

K.

What do you think of this story? Let’s exchange in the comments area below!